What is a transformer aluminum strip?

Aluminum foil for transformer winding refers to the aluminum strip and foil used as conductive materials for transformer windings. They have the characteristics of high conductivity, smooth surface, and no burrs. They are ideal materials for the production of dry-type transformers. Aluminum strips are used for transformer are produced by slitting aluminum coils through slitting equipment.

Aluminum strip for transformer usually use 1000 series alloys, such as 1060, 1050, 1050A, 1060, 1070, 1070A, and 1350, with a state of O (Soft) and high conductivity, usually better than 60% IACS.

In addition, It can be used for semi-automatic and fully automatic winding machine winding. Aluminum foil strip is suitable for oil-immersed and dry-type transformers, also called aluminum foils strips for dry-type transformers.

In low-frequency transformers, aluminum foil strip gradually replace copper in transformers. Still, in ultra-high voltage and high-power transformers, copper strip has more advantages than aluminum strip.

Hot-selling transformer aluminum strip

Currently, the most commonly used aluminum strip for making transformer windings are 1050, 1060, and 1070 Temper O aluminum foil strip. Henan Xienuo can produce it according to customer needs, with low tolerances, high conductivity, and no burrs on the edges.

Basic information

- Product name: Aluminum foil for transformer windings

- Alloy: 1050, 1060, 1070, 1350

- Temper: O

- Thickness: 0.2mm-3.5mm

- Width: 10mm-1600mm

- Edge: Slit/Round

- Quantity tolerance: ±10%

- Paper Core Internal Diameter: 76mm, 150mm, Ø300mm, Ø400mm paper core, the diameter of the paper tube is related to the thickness of the foil and strip

- Applications: Transformer winding

- Packaging: Wooden Pallet/Wooden Case

- Payment Terms: 30% TT deposit and 70% balance before shipment, 100% LC at sight

- MOQ: 5 Tons

- Sample: Available

- Delivery Time: 7-30 working days, depends on your specific needs

- HS Code: 76069100.00

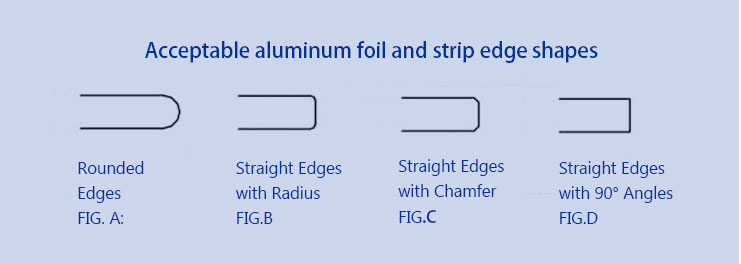

Edge(ends) shapes

Acceptable edge shapes:

- FIG. A: Rounded Edges

- FIG. B: Straight Edges with Radius

- FIG. C: Straight Edges with Chamfer

- FIG. D: Straight Edges with 90°Angles

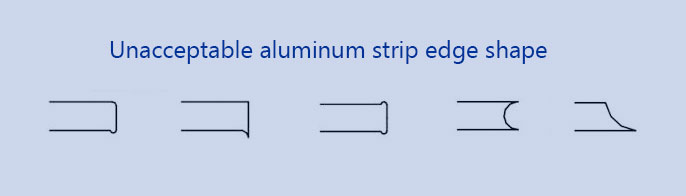

Unacceptable edge shape:

Thickness tolerance

| Thickness range(mm) | Thickness tolerance(mm) |

|---|---|

| 0.08-0.20 | ±8% of nominal thickness |

| >0.20-0.40 | ±0.02 |

| >0.40-0.80 | ±0.03 |

| >0.80-1.10 | ±0.04 |

| >1.10-1.40 | ±0.05 |

| >1.40-2.00 | ±0.06 |

| >2.00-2.50 | ±0.07 |

| >2.50-3.00 | ±0.08 |

Width tolerance

| Thickness range(mm) | Width tolerance (+) | ||||

|---|---|---|---|---|---|

| <=100.0 | >100.0-300.0 | >300.0-500.0 | >500.0-1250.0 | >1250.0-1500.0 | |

| >0.08-0.20 | 0.3 | 0.4 | 0.6 | 1.0 | 2.0 |

| >0.20-0.60 | 0.3 | 0.4 | 0.6 | 1.5 | 2.5 |

| >0.60-1.00 | 0.3 | 0.5 | 1.0 | 1.5 | 2.5 |

| >1.00-2.00 | 0.4 | 0.7 | 1.2 | 2.0 | 2.5 |

| >2.00-3.00 | 1.0 | 1.0 | 1.5 | 2.0 | 2.5 |

Length tolerance

The tolerance for length shall be from -0% to +2%, considering the total indicated on the Purchase Order.

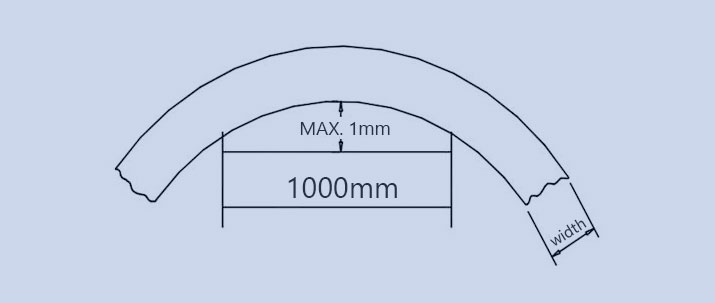

Lateral curvature tolerance

| Width (mm) |

Lateral Curvature Measured on 2000/1000mm Strip length |

|

|---|---|---|

| Over | Up to and Including | |

| 15 | 100 | 6mm /1.5mm |

| 100 | 300 | 4mm /1.5mm |

| 300 | 600 | 3mm /0.7mm |

| 600 | 1540 | 2mm / 0.5mm |

Edge (Burr, Camber, Layering)

| Thickness | Burr | Camber | Layering |

|---|---|---|---|

| <=0.20 | <=0.03 | <=0.5 | <=4 |

| >0.20 | <=0.05 | <=2 | <=5 |

Conductivity

- 1050 is better than 60% IACS.

- 1060 is be better than 61.5% IACS.

- 1070 is better than 62.7% IACS.

- 1350 is better than 62% IACS.

Packaging and shipping

Xienuo's packaging of aluminum foil strip for transformers winding are mainly wooden pallets and wooden boxes. Each roll of aluminum foil or strip is wrapped with a plastic film, and a desiccant is placed inside. The length and weight of the strip are the same. The packaging mark can be filled in according to requirements, usually including Product type, size, weight (gross and net), production date, serial number, brand, manufacturer, etc.

Wooden Pallet: Standard export package, no fumigation;

Standard Pallet size: 1.1m x 1.1m x 0.8m (can be customized);

Gross weight: 1000kg;

Loading capacity: 4 pallets per 20′ FCL, 8 pallets per 40′ FCL

Or as per the customer’s requirements.

Wooden Box: Standard export package with fumigation certificate

The packaging is sturdy to ensure it does not fall apart and does not allow moisture to enter.

Certificates and test reports

Each purchase order is provided with a material certificate that meets the customer's needs. It should conduct at least the following tests:

- Chemical composition (confirmation of aluminum purity)

- Conductivity

- Mechanical properties (tensile and bending tests)

- Hardness measurement

Alloy and temper of Aluminum foil strip for transformers winding

- 1050 O aluminum foil for transformer winding

- 1060 O aluminum foil for transformer winding

- 1070 O aluminum foil for transformer winding

- 1350 O aluminum foil for transformer winding

Chemical composition

| Component | Content | |||

|---|---|---|---|---|

| Elements | 1050(max%) | 1060(max%) | 1070(max%) | 1350(max%) |

| Silicon, Si | 0.25 | 0.25 | 0.2 | 0.1 |

| Iron, Fe | 0.40 | 0.35 | 0.25 | 0.4 |

| Magnesium, Mg | 0.05 | 0.03 | 0.03 | |

| Zinc, Zn | 0.05 | 0.05 | 0.04 | 0.05 |

| Manganese, Mn | 0.05 | 0.03 | 0.03 | 0.01 |

| Titanium, Ti | 0.03 | 0.03 | 0.03 | 0.01 |

| Copper, Cu | 0.05% | 0.05 | 0.04 | 0.05 |

| Vanadium, V | 0.05 | 0.05 | 0.01 | |

| Cr | 0.01 | |||

| B | 0.05 | |||

| Aluminum, Al | >=99.5 | >=99.6 | >=99.7 | >=99.5 |

Mechanical properties

| Alloy | Temper | Thickness /mm | Tensile strength MPa | Elongation (%) | 20 ℃ Conductivity (IACS) |

|---|---|---|---|---|---|

| 1050, 1060, 1070, 1350 | O(Soft) | 0.08-0.20 | 60-95 | >=20 | >= 61.7% (min) |

| >0.20-3.00 | >=25 |

Production Process

- Material preparation

- Aluminum slab is heated in the furnace

- Milling and finishing

- Rough rolling

- Finish rolling

- Annealing

- Rewinding

- Slitting

- Packaging and transportation

Features

- Excellent elongation and tensile strength

- Good plasticity, uniform thickness,

- No burrs on the edges, safe to use

- Excellent electrical and thermal conductivity;

- Good corrosion resistance and weldability;

- Uniform and smooth surface, clean and free of oil stains

- High-temperature resistance, can withstand high-temperature test of 130℃

- Low weight and cheap price

Why choose us?

Xienuo is a professional manufacturer of aluminum foil for transformer winding. It can slit aluminum strips according to the width required by users. The surface is smooth and scratch-free, and the maximum absolute roughness is 5-7 micron inches. The edge chamfering can reach 100%, without burrs, scratches, and other unfavorable factors. The resistivity and conductivity are both better than national standards and industry standards for transformers of China. It is mainly used in aluminum strips for dry-type transformers, reactors of large and medium-sized transformers, and other related fields.

FAQ

What metal is used for the windings in a transformer?

The windings of transformers are often made of copper or aluminum metal. These metals are chosen primarily based on their electrical and thermal properties. Some special-purpose transformers also use copper-aluminum alloy, silver, and other metal materials.

How is Aluminum Foil For Transformer Winding produced?

Aluminum foil for transformer winding is usually obtained by slitting aluminum strips through slitting equipment according to customer requirements.

Aluminum strips used in transformers have extremely high requirements on the edges to ensure the safe use of the transformer. In the actual production process, due to the influence of the hardness of the aluminum strip and the unloading speed, it is difficult to effectively control the edges of the transformer aluminum strip, but Xienuo's engineers solved the problem.

What is foil winding in transformer?

Foil winding in transformers refers to a specific technique used in the construction of transformer windings. Instead of using traditional wire conductors, foil windings utilize thin strips or sheets of conductive material, often made of copper or aluminum. These conductive foils are layered or wound together to form the transformer's winding.

Key features of foil winding in transformers include:

- Flat Conductive Foils

- Low-Profile Design

- Reduced Proximity Effect

- Improved Cooling

- High Current Capacity

- Precision Winding

Can aluminum be used in transformer?

Of course, aluminum foil for transformer winding is the key raw material for manufacturing transformer windings. Using aluminum foil windings can reduce the size and weight of the transformer.

Aluminum foil windings also have the advantages of good insulation performance, flame retardancy, no pollution, small partial discharge, moisture resistance, smooth and reliable operation, low noise, and low maintenance costs.

What are the disadvantages of aluminum winding in transformer?

Although the aluminum foil windings of transformers have the characteristics of light weight and low cost, they also have some disadvantages compared to copper when used in transformers. The strength and corrosion resistance of aluminum strips are slightly worse than those of copper strips. Secondly, the linear expansion coefficient of aluminum strip is larger than that of copper strip, which can easily cause deformation. Therefore, in some special cases, aluminum strips cannot replace copper strips.

- Poor electrical conductivity

- Poor corrosion resistance

- Poor thermal stability

- Large expansion coefficient

- Easily oxidized

- Poor mechanical properties

- High frequency loss

- Poor welding performance

What are the advantages of aluminum winding in transformer?

Transformer aluminum strip is a material used in transformer manufacturing. It performs the functions of electrical conduction and heat transfer. Aluminum strips have some advantages over copper strips. First, the cost of aluminum strip is lower, which can reduce the cost of transformer manufacturing. Secondly, the aluminum strip has a smaller density and lighter weight, which can reduce the weight of the transformer. At the same time, the electrical conductivity of aluminum strips is also relatively good and is not susceptible to current shock.

Which winding is better copper or aluminum in transformer?

There are some differences between using copper or aluminum windings in dry-type transformers, and the choice depends on several factors, including performance, cost, weight, and application.

Here are some of the main differences and general selection considerations:

- Mechanical properties: Copper strip is better than aluminum strip

- Mechanical strength: Aluminum strips are worse than copper strips. Aluminum foils strips are easy to break

- Aluminum core transformers have poor short-circuit resistance;

- Thermal stability: The aluminum strip is poor. The maximum allowable temperature of the aluminum strip is lower than that of the copper strip.

- Impact resistance: The welded joints of aluminum windings in the transformer are easily burned under lightning impact and current, which can easily cause overheating;

- Aluminum strips are prone to oxidation and corrosion;

- Aluminum winding in transformers mostly use copper-aluminum foil welding or copper-aluminum joints to connect the windings and leads. The mechanical strength of the connection is poor, and the welding process is complicated. The connection is easy to disconnect after severe vibration, and chemical reactions are easy to occur in the connection after long-term operation, resulting in the resistivity increases, causing local overheating;

- Production cost: low for aluminum strip and high for copper strip;

Generally speaking, smaller, low-frequency transformers can use aluminum strips, while larger, higher-performance, high-frequency, high-temperature transformers need to use copper strips.

What is the hardness of aluminum foil for transformer windings?

The typical Brinell hardness of the material must be determined after the annealing treatment (Typical Brinell hardness value: 18HB).