What is 1235 aluminum foil?

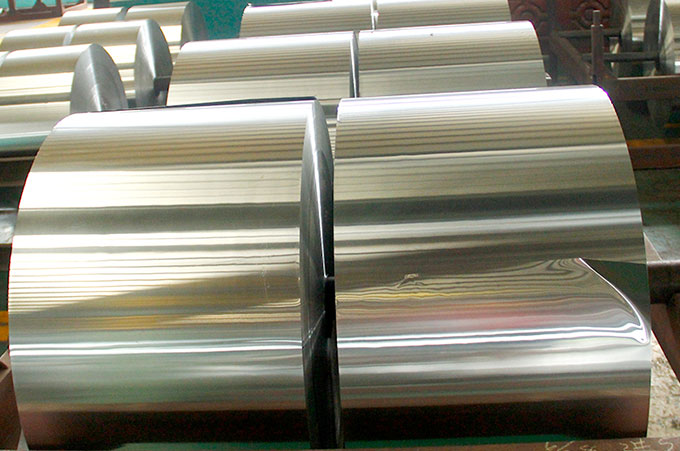

1235 aluminum foil has an aluminum content of not less than 99.35%. It has good anti-rust properties, formability, and weldability. It is widely used in wires and cables, tapes, battery foils, household foils, container foils, pharmaceutical foils, soft packages, and Heat sealing.

Customizable specifications

Xienuo Aluminum can process 1235 aluminum foil with a thickness of 0.0065mm - 0.2mm. It has a small amount of stock and can also be produced according to ASTM B209, ASTM B479, EN573-1, EN 546, QQA 1876, and other standards. Our 1235 aluminum foil has stable quality and excellent mechanical properties.

In addition, we also provide additional processing services such as 1235 aluminum foil slitting, coating, embossing, and oxidation.

| Item | Content |

|---|---|

| Alloy | 1235 Aluminum Foil |

| Temper | O, H14, H16, H18, H19, H22, H24 |

| Type | Heavy gauge foil, Medium gauge foil, Light gauge foil |

| Thickness(mm) | 0.01-0.2 |

| Thickness Tolerance(mm) | ±0.01 |

| Width(mm) | 100-1700 |

| Length(mm) | Customizable |

| Coil ID | 75mm, 76 mm, 150 mm, 152 mm |

| Coil Weight | 30kg-200kg, or according to your needs |

| Treatment | Mill finish, Coated, |

| Standard | AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc. |

| Typical Use | Cable foil, aluminum foil tape, battery foil |

| MOQ | Generally, the trial order will be accepted. |

| HS Code | 76071900 |

| Lead Time | 7-35 days delivery, global export |

| Price Term | CIF CFR FOB EX-WORK or according to negotiation |

| Payment Term | TT, LC at sight or according to negotiation |

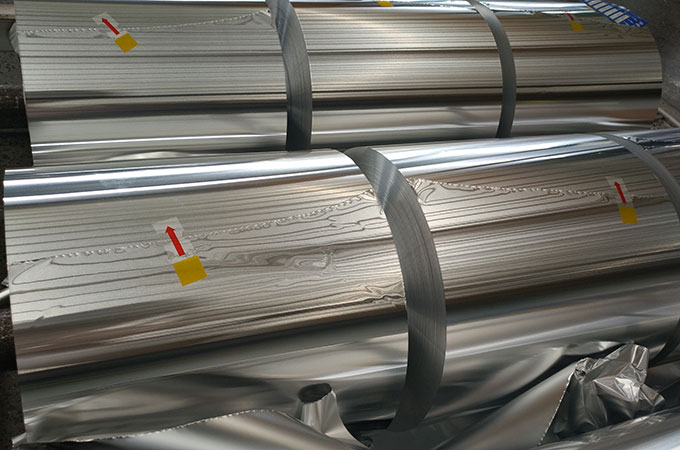

| Packaging |

Standard seaworthy export packaging. With

protection, or based on the customer's requirement Vertical packaging (eye to sky) Horizontal packaging(eye to side) |

| Loading capacity (for reference only) |

1x20" container can load 18-22 tons Can load 20-24 tons in 1x40" container The weight of each wooden box is from 0.5MT-1MT, or according to customer's requirements |

| Supply Ability | 1, 000 Tons per Month |

1235 aluminum foil performance advantages

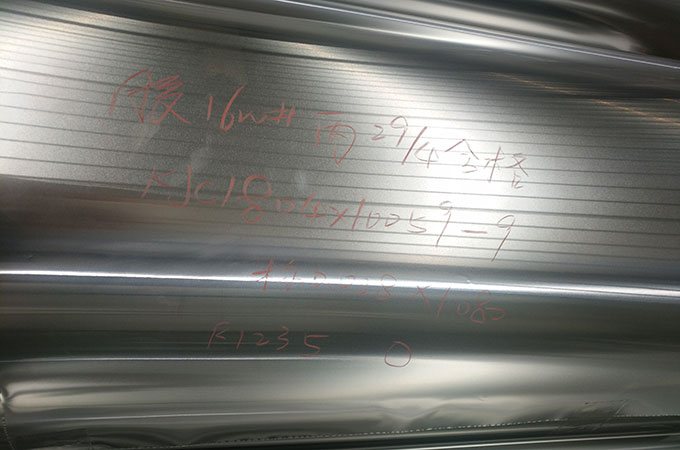

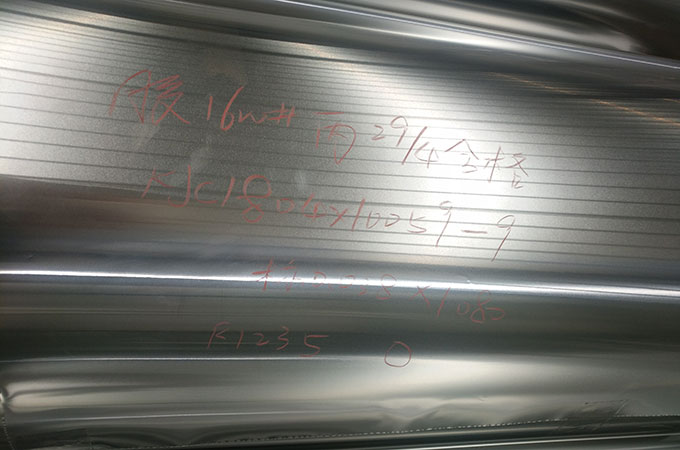

- The surface of the aluminum foil is uniform in color, clean, and smooth, with no obvious traces of roller marks, pinholes, corrosion, etc.;

- No color difference, no rolling defects such as creases, spots, bright lines, etc.;

- The surface is degreased and clean, with no serious oil smell and no oil spots visible to the naked eye;

- It has good mechanical properties, excellent performance, easy processing, and good anti-rust effect.

Basic Properties

Component Elements Properties

| Component | Content (%) |

|---|---|

| Fe | 0.65 |

| Si | |

| Cu | 0.05 |

| Mn | 0.05 |

| Mg | 0.05 |

| Zn | 0.1 |

| V | 0.05 |

| Ti | 0.06 |

| Other | 0.03 |

| Al | 99.35 |

Physical Properties

| Physical Properties | Metric | English | Comments |

|---|---|---|---|

| Density | 2.705 g/cc | 0.09772 lb/in³ | AA; Typical |

Mechanical Properties

| Alloy | Temper | Tensile Strength(psi) | Elongation(%) | Yield Strength(psi) |

|---|---|---|---|---|

| 1235 | O | 13 x 1000 psi | 35 | 5 x 1000 psi |

|

H12 H22 |

16 x 1000 psi | 12 | 15 x 1000 psi | |

|

H14 H24 |

18 x 1000 psi | 9 | 17 x 1000 psi | |

|

H16 H26 |

21 x 1000 psi | 6 | 20 x 1000 psi | |

| H18 | 24 x 1000 psi | 5 | 22 x 1000 psi |

Thermal Properties

| Properties | Metric | English | Comments |

|---|---|---|---|

| Heat of Fusion | 390 J/g | 168 BTU/lb | - |

| CTE, linear |

23.6 µm/m-°C @Temperature 20.0 - 100 °C |

13.1 µin/in-°F @Temperature 68.0 - 212 °F |

- |

| - |

25.5 µm/m-°C @Temperature 20.0 - 300 °C |

14.2 µin/in-°F @Temperature 68.0 - 572 °F |

average |

| Specific Heat Capacity | 0.900 J/g-°C | 0.215 BTU/lb-°F | - |

| Melting Point | 645 - 655 °C | 1190 - 1210 °F | - |

| Solidus | 645 °C | 1190 °F | - |

| Liquidus | 655 °C | 1210 °F | - |

Some applications of 1235 aluminum foil

Flexible packaging

- Temper: 1235 O

- Thickness: 0.007~0.01

- Usage: Outer packaging of candy, milk and dairy products, powdered food, beverages, tea, bread and various snacks

Air conditioners aluminum foil

- Alloy: 1235

- Temper: O, H14, H16, H22, H26, H24

- Thickness: 0.014mm-0.2mm

- Usage: Heat exchanger fin materials

Household aluminum foil

- Alloy: 1235

- Temper: O, h18, H22

- Thickness: 0.008mm-0.05mm

- Usage: Aluminum foil for cooking, grilling, BBQ, baking

Aluminum foil container

- Alloy: 1235

- Temper: O, H22, H24

- Thickness: 0.03mm-0.2mm

Aluminum foil adhesive tape

- Alloy: 1235

- Temper: O, H18

- Thickness: 0.01mm-0.05mm

- Usage: Suitable for various types of transformers, mobile phones, computers, PDAs, and other electronic products where electromagnetic shielding is required.

The production process of hard (Temper H18) aluminum foil tape does not require annealing, but sometimes requires baking oil.

Soft (Temper O) aluminum foil tape needs to be annealed to make its performance softer.

Cable shielding aluminum foil

- Temper: 1235 O

- Thickness: 0.006mm - 0.04mm

- Usage: Wrapping weak wires for shielding

Cigarette packaging(Cigarette lined paper)

- Temper: 1235 O

- Thickness: 0.006mm - 0.007mm

- Usage: Used in cigarette packaging after being lined, printed or painted.

Pharmaceutical aluminum foil

- Alloy: 1235

- Temper: H14,H16,H18

- Thickness: 0.016mm - 0.2mm

Electronic aluminum foil

- Temper: 1235 O

- Thickness: 0.0045~0.009

- Usage: electronic capacitor

Battery foil

- Temper: 1235-H18

- Thickness: 0.012~0.035,

- Usage: Products used as current collector materials for lithium ion batteries.

Heat seal foil

- Alloy: 1235

- Temper:O, H18, H22, H24

- Thickness: 0.03mm – 0.060mm, commonly used 0.038mm

1235 O H19 aluminum foil

Aluminum 1235-O Foil

| Properties | Metric | English | Comments |

|---|---|---|---|

| Hardness, Brinell | 45 | 45 | 500 kg load with 10 mm ball. Calculated value. |

| Tensile Strength, Ultimate | 75.0 MPa | 10900 psi | - |

| Tensile Strength, Yield | 30.0 MPa | 4350 psi | - |

| Elongation at Break | 2.4 % | 2.4 % | Foil |

| Tensile Modulus | 69.0 GPa | 10000 ksi | Compressive modulus in is typically about 2% higher for Al alloys |

| Poissons Ratio | 0.33 | 0.33 | Estimated from trends in similar Al alloys. |

| Shear Modulus | 26.0 GPa | 3770 ksi | Estimated from similar Al alloys. |

| Shear Strength | 100 MPa | 14500 psi | Calculated value. |

| Properties | Metric | English | Comments |

|---|---|---|---|

| Electrical Resistivity | 0.00000280 ohm-cm | 0.00000280 ohm-cm | - |

| Thermal Conductivity | 230 W/m-K | 1600 BTU-in/hr-ft²-°F | - |

Aluminum 1235-H19 Foil

| Properties | Metric | English | Comments |

|---|---|---|---|

| Hardness, Brinell | 45 | 45 | 500 kg load with 10 mm ball. Calculated value. |

| Tensile Strength, Ultimate | 165 MPa | 23900 psi | - |

| Tensile Strength, Yield | 145 MPa | 21000 psi | - |

| Elongation at Break | 2.5 % | 2.5 % | Foil |

| Tensile Modulus | 69.0 GPa | 10000 ksi | Compressive modulus in is typically about 2% higher for Al alloys |

| Poissons Ratio | 0.33 | 0.33 | Estimated from trends in similar Al alloys. |

| Shear Modulus | 26.0 GPa | 3770 ksi | Estimated from similar Al alloys. |

| Shear Strength | 100 MPa | 14500 psi | Calculated value. |

| Properties | Metric | English | Comments |

|---|---|---|---|

| Electrical Resistivity | 0.00000300 ohm-cm | 0.00000300 ohm-cm | - |

| Thermal Conductivity | 230 W/m-K | 1600 BTU-in/hr-ft²-°F | - |

1235 vs. 8001 aluminum foil

| Item | 1235 aluminum foil | 8011 aluminum foil |

|---|---|---|

| Alloy element composition | Pure aluminum, Fe | Fe+Si |

| annealing | The temperature is lower and the annealing time is almost the same | The temperature is high and the annealing time is almost the same |

| tensile strength | 12000psi-26000psi | 8000 psi -28000 psi |

| Elongation | Almost the same, 8011 is slightly higher | |

| density | 2.7 g/cm³ 2.71 g/cm³ | 2.7 g/cm³ 2.71 g/cm³ |

| melting point | 660°C | |

| Conductive properties | high low | high low |

1235 and 8011 aluminum foil jumbo roll have slightly different properties due to different alloy elements and processing techniques, but they can be substituted for each other in certain specific usage scenarios, such as household aluminum foil, pharmaceutical packaging aluminum foil and other industries.

Why choose us

Xienuo is a 1235 aluminum foil manufacturer integrating R&D, production and sales. The company strictly selects raw materials, controls the production process, and operates meticulously. It is guaranteed that 1235 aluminum foil meets relevant standards.

High quality

The 1235 aluminum foil products produced have good appearance, no black wires, no bright lines, no holes, high strength and good ductility.

Good price

The company has advanced production equipment, large production capacity, fast delivery, and the price of 1235 aluminum foil is reasonable.