What is 5052 aluminum foil

5052 aluminum foil is a hard aluminum foil with high strength and corrosion resistance. It has the characteristics of high fatigue strength, high rust and corrosion resistance, and good weldability.

Widely used in aerospace, automotive industry, construction engineering and other fields. It is also a high-quality food packaging material and is used to make lunch box materials, etc. In addition, 5052 aluminum foil is often used in honeycomb aluminum foil.

Customizable specifications

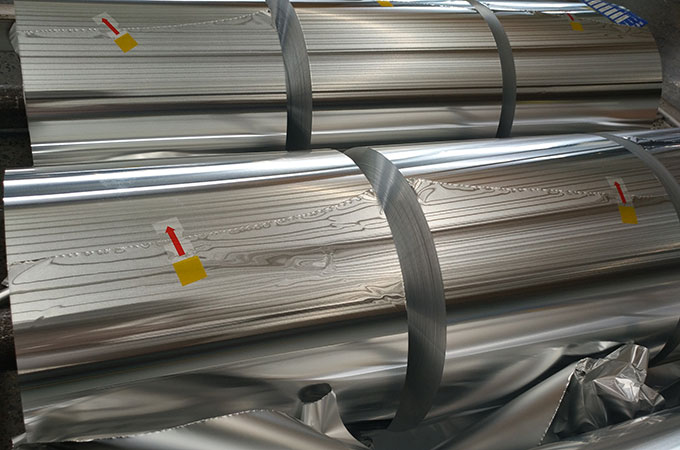

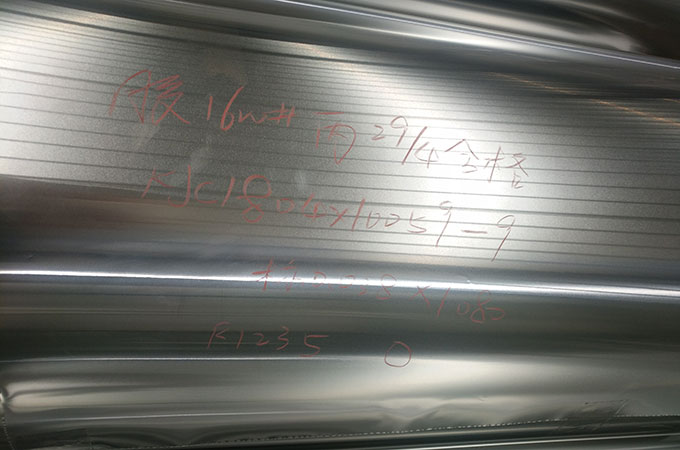

Henan Xienuo Enterprise is a large-scale 5052 aluminum foil jumbo roll manufacturer. It can produce 5052 aluminum foil with thickness ranging from 0.014mm to 0.2mm according to ASTM B209, EN573-1S, GB/T3190-1996 or other standards. Xienuo's 5052 aluminum foil has no black wire, no Bright threads, no pinholes, tested for mold, and comply with safety and health standards, Delivery within 7-35 days, exported worldwide.

| Item | Content |

|---|---|

| Alloy | 5052 Aluminum foil |

| Temper | F, O, H14, H16, H18, H19, H22, H24, H26, H28 |

| Type | Heavy gauge foil, Medium gauge foil, Light gauge foil |

| Thickness(mm) | 0.014-0.2 |

| Thickness tolerance(mm) | ±0.01 |

| Width(mm) | 100-1700 |

| Length(mm) | Customizable |

| Coil ID | 75mm, 76 mm, 150 mm, 152 mm |

| Coil Weight | 30kg-200kg, or according to your needs |

| Treatment | Mill finish, Coated, |

| Standard | AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc. |

| Typical Use | Lunch box materials, honeycomb aluminum foil, acoustic materials |

| MOQ | Generally, the trial order will be accepted. |

| HS code | 76071900 |

| Lead Time | 7-35 days delivery, global export |

| Price Term | CIF CFR FOB EX-WORK or based on negotiation |

| Payment Term | TT, LC at sight or based on negotiation |

| Supply Ability | 1, 000 Tons per Month |

Regular Temper:

- 5052 O aluminum foil

- 5052 H18 aluminum foil

- 5052 H19 aluminum foil

- 5052 H26 aluminum foil

Property

Chemical Composition

5052 aluminum foil is an Al-Mg series alloy aluminum foil that has the characteristics of 5000 series aluminum alloy, such as: good anti-rust, anti-corrosion properties, good formability and welding properties.

| Component | Content(%) |

|---|---|

| Iron (Fe) | 0.4 |

| Silicon (Si) | 0.25 |

| Copper (Cu) | 0.1 |

| Manganese (Mn) | 0.1 |

| Magnesium (Mg) | 2.2 - 2.8 |

| Zinc (Zn) | 0.1 |

| Chromium (Cr) | 0.15-0.35 |

| Titanium (Ti) | - |

| Aluminum (Al) | Rem |

Physical properties

| Properties | Metric | English | Comments |

|---|---|---|---|

| Density | 2.68 g/cc | 0.0968 lb/in³ | AA; Typical |

Mechanical properties

| Alloy | Temper | Tensile Strength(Mpa) | Elongation(%) | Yield Strength(psi) |

|---|---|---|---|---|

| 5052 | O | 175-225 | 25 | 13000 |

|

H12 H22 |

195-250 | 12 | 28000 | |

|

H14 H24 |

250-300 | 10 | 31000 | |

|

H16 H26 |

≥270 | 8 | 35000 | |

| H18 | ≥300 | 6-7 | 37000 |

Thermal Properties

| Properties | Metric | English | Comments |

|---|---|---|---|

| CTE, linear 68°F | 23.8 µm/m-°C | 13.2 µin/in-°F | AA; Typical; Average over 68-212°F range. |

| CTE, linear 250°C | 25.7 µm/m-°C | 14.3 µin/in-°F | Average over the range 20-300ºC |

| Specific Heat Capacity | 0.88 J/g-°C | 0.21 BTU/lb-°F | Estimated from trends in similar Al alloys. |

| Melting Point | 607 – 649 °C | 1125 – 1200 °F | AA; Typical range based on typical composition for wrought products 1/4 inch thickness or greater |

| Solidus | 607 °C | 1125 °F | AA; Typical |

| Liquidus | 649 °C | 1200 °F | AA; Typical |

Processing Properties

| Properties | Metric | English | Comments |

|---|---|---|---|

| Annealing Temperature | 343 °C | 650 °F | holding at temperature not required |

| Hot-Working Temperature | 260 – 510 °C | 500 – 950 °F |

Electrical Properties of 5052 H19 foil

| Properties | Metric | English | Comments |

|---|---|---|---|

| Electrical Resistivity | 4.99e-006 ohm-cm | 4.99e-006 ohm-cm | AA; Typical at 68°F |

| Thermal Conductivity | 138 W/m-K | 960 BTU-in/hr-ft²-°F | AA; Typical at 77°F |

Data Sources: https://asm.matweb.com/search/SpecificMaterial.asp?bassnum=ma5052h19

5052 Aluminum foil uses

Lunch box materials

5052 aluminum foil can be used in lunch box materials. It is hygienic and of reliable quality. It is one of the commonly used raw materials for aluminum foil lunch boxes.

In addition, 8011, 3004, and 8006 aluminum foil jumbo roll are often used in lunch box materials.

- Alloy: 5052 aluminum foil

- Thickness: 0.03-0.2mm

- Width: 100-1650mm

- Temper: H16, H26, H14, H24, H18

Compared with 8011, 3004, and 8006 aluminum foil, 5052 aluminum foil has better molding performance and stronger hardness.

Aluminum honeycomb core

The aluminum honeycomb core material is a hexagonal honeycomb core made of 3003 aluminum foil, 3004 aluminum foil, and 5052 aluminum foil. The aluminum foil thickness is 0.02-0.06mm. The aluminum honeycomb side length models include 5mm, 6mm, 8mm, 10mm, 12mm, etc.

- Alloy: 5052 aluminum foil

- Width: 100-1650mm

- Thickness:0.02mm-0.06mm

- Temper: H18

In addition, 5052 aluminum foil is often used to make cans, umbrella frames, trolley cases, door handles, high-end signs, etc.

Production Process

- Raw material preparation: Use high-purity aluminum alloy materials as raw materials.

- Continuous casting: The molten aluminum alloy is poured into the gate of the continuous casting machine, and after cooling, it forms a continuous casting billet, that is, an aluminum strip.

- Rough rolling: The continuous casting billet is rolled through a rough rolling mill, so that its size gradually becomes thinner and wider, and gradually forms the preliminary form of aluminum foil.

- Cold rolling: The rough-rolled aluminum strip is generally rolled to 0.35mm through multi-pass thin rolling.

- Stress-relieving tempering: Keep the material warm for a period of time at a certain temperature to eliminate deformation resistance.

- Finish rolling: further rolling to meet customer needs.

- Treatment: further surface treatment according to needs.

Why choose us

Henan Xienuo Enterprise is a large-scale 5052 aluminum foil manufacturer. The company's history can be traced back to Shunyuan Aluminum, which was established in 1999. We have the most advanced foil rolling equipment and first-class professionals. With a monthly aluminum foil production capacity of 1, 000 tons, we can meet your needs Any new projects.

Certification:

- ISO9001

- ISO9002

- RoHS

- SGS

- FDA

Extra services:

- Striping

- Color coating

- Embossed

- Compound

- Printing

- Glue