What is a 3003 aluminum circle?

3003 aluminium alloy mainly adds an Mn element, which is a typical anti-rust alloy metals. 3003 aluminum circles are also called 3003 discs or 3003 aluminum round plates, It’s strength is about 10% higher than that of 1000 series discs. It is a good alternative to steel and 1000 series aluminum discs.

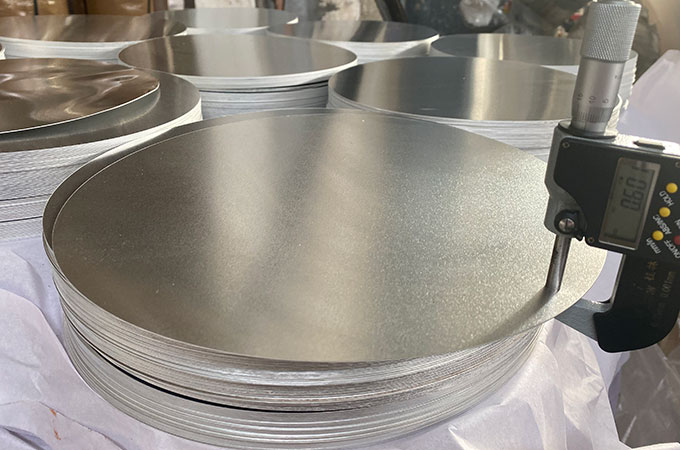

Usually, a 3003 aluminum circle is produced from 3003 aluminum plate, sheet, coil, strip or foil through cutting equipment.

| European Standard | OLD | WNr | UNS | ISO | USA (AA) | GERMANY (DIN) |

|---|---|---|---|---|---|---|

| AW-AlCu4Mg1 | AU4G1 | 3.0517 | A93003 | AlCu4Mg | 3003 | AlCuMg2 |

3003 Aluminum circle for sale

- Alloy:3003

- Temper: O (soft), H12, H14, H16, H18, H22, H24, H26, H111, H112, H32, H34, H36, etc.

- Process type: DC (Hot-rolled), CC (Casting rolling)

- Production method: stamping (mold stamping), cutting

- Thickness: 0.03 mm -7 mm

- Thickness tolerance: Detailed

- Diameter: 20 mm -1500 mm, diameter list

- Quality: Totally free from defects like roll makers, edge damage, oil stains, white rust, dents, scratches, etc.

- Shape: Circle, Square (rounded corners), Oval, Rectangle

- Surface treatment: coating (blue film, electrostatic blue film, transparent film, black and white film, laser film), paper clamping, prepainting, etc.

- Deep processing: anodizing, embossed, stamping, orange peel, laser engraving, color coated, printing, etc.

- Standards: 3003 GB/T 3190-1996, AlMn1Cu ISO 209.1-1989, JIS H4000-1999 JIS H4100-1999, 31000 IS 736-2001, AMu/1400 FOCT4785-1974, EN AW-3003/AlMn1Cu EN 573-3-1994, AlMnCu/3.0517 DIM1725-1-1986, 3003 (A-M1) NFA50-411 NFA50-451, 3103 (N3) BS 1470-1988, 3003/A93003 AA/UNS or according to your needs

- Weight per pallet: Regular 500kg-1000kg, or according to your needs

- HS code:76069100

- Lead Time: 7-35 days delivery, global export

- Price Term: CIF, CFR FOB EX-WORK or according to negotiation

- Payment Term: LC at sight or according to negotiation

- Packaging and packing: Standard seaworthy export packaging. With protection(covering with brown paper and plastic film). Waterproof, moisture-proof.Finally, the aluminum circle is fixed on a wooden pallet/wooden case. 1-3 tons in 1 wooden pallet. 18-22 tons in a 1x20' container.

- Supply Ability:1, 000 Tons per Month

- Loading Port: Any port of China, Shanghai, Ningbo, Qingdao

Please contact us for detailed categories or more information, or samples, samples for free

Diameter list

| Diameter range | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| >=20 | >=140 | >=170 | >=200 | >=250 | >=300 | >=400 | >=500 | >=600 | >=700 | >=800 |

| 20 | 140 | 170 | 200 | 250 | 300 | 400 | 500 | 600 | 700 | 800 |

| 25 | 141 | 172 | 203 | 252 | 305 | 405 | 505 | 610 | 705 | 810 |

| 93 | 142 | 173 | 205 | 254 | 310 | 410 | 510 | 615 | 710 | 838 |

| 100 | 143 | 175 | 210 | 255 | 312 | 420 | 515 | 619 | 720 | 890 |

| 105 | 144 | 176 | 211 | 258 | 315 | 425 | 520 | 630 | 730 | 902 |

| 109 | 145 | 177 | 212 | 260 | 320 | 430 | 525 | 635 | 740 | 945 |

| 110 | 147 | 178 | 215 | 267 | 325 | 435 | 530 | 645 | 760 | 960 |

| 112 | 149 | 180 | 216 | 268 | 330 | 440 | 540 | 650 | 770 | 1000 |

| 115 | 150 | 181 | 217 | 270 | 335 | 445 | 545 | 655 | 780 | 1150 |

| 118 | 153 | 182 | 218 | 272 | 340 | 450 | 550 | 665 | 1200 | |

| 120 | 154 | 183 | 220 | 274 | 345 | 455 | 560 | 670 | ||

| 121 | 155 | 184 | 221 | 275 | 350 | 460 | 565 | 680 | ||

| 122 | 157 | 185 | 222 | 277 | 355 | 465 | 570 | 690 | ||

| 123 | 158 | 188 | 225 | 278 | 360 | 470 | 575 | |||

| 124 | 160 | 190 | 226 | 280 | 364 | 475 | 580 | |||

| 127 | 161 | 192 | 230 | 282 | 368 | 480 | 585 | |||

| 128 | 162 | 193 | 233 | 285 | 370 | 485 | ||||

| 129 | 163 | 195 | 235 | 290 | 375 | 490 | ||||

| 130 | 164 | 198 | 237 | 292 | 380 | 495 | ||||

| 132 | 165 | 238 | 293 | 385 | ||||||

| 133 | 166 | 240 | 295 | 390 | ||||||

| 134 | 167 | 242 | 395 | |||||||

| 135 | 168 | 245 | ||||||||

| 136 | 169 | 249 | ||||||||

| 137 | ||||||||||

| 138 | ||||||||||

| 139 | ||||||||||

Diameter tolerances

| Blanked and Sheared aluminum Circle Products | |||

|---|---|---|---|

| Thickness(mm) | Diameter Range (D)(mm) | ||

| D <= 455 | 455 < D <=1000 | 1000 < D <=1500 | |

| .4 - 6.0 | +/-.079 | +/-.099 | +/-.018 |

|

*The maximum dimension may vary according to individual specifications |

|||

Component Elements Properties

The main alloying element of 3003 aluminium alloy is Mn. It has a strong anti-rust performance and higher strength than the 1000 series. It is a good substitute for 1060 aluminum discs among the metal materials used in making cookware.

| Component | Content (%) |

|---|---|

| Iron, Fe | <= 0.70 |

| Silicon, Si | <= 0.60 |

| Copper, Cu | 0.05 - 0.20 |

| Manganese, Mn | 1.0 - 1.5 |

| Zinc, Zn | <= 0.10 |

| Other, each | <= 0.03 |

| Other, total | <= 0.15 |

| Aluminum, Al | 96.7 - 99 |

Performance parameters

| Alloy | 3003 Aluminum circle | ||||||

|---|---|---|---|---|---|---|---|

| Temper | O(soft) | H12, H22 | H14, H24 | H16, H26 | H18, H28 | H112 | |

| Physical Properties | Density | 2.73 g/cm³ | |||||

| Mechanical Properties | Hardness, Brinell | 28 | 35 | 40 | 47 |

55 70(Knoop) |

|

| Tensile Strength, Ultimate |

110 MPa 18.0 MPa @Temperature 400°C 29.0 MPa @Temperature 300°C 60.0 MPa @Temperature 200°C 90.0 MPa @Temperature 100°C 110 MPa @Temperature 25.0℃ 115 MPa @Temperature -30.0°C 150 MPa @Temperature -100°C 230 MPa @Temperature -200°C 97.0 - 130 MPa @Thickness 0.152-76.2 mm |

115 - 160 MPa @Thickness 0.432 - 50.8 mm |

152 MPa 18.0 MPa @Temperature 400°C 29.0 MPa @Temperature 300°C 96.0 MPa @Temperature 200°C 145 MPa @Temperature 100°C 150 MPa @Temperature -30.0 °C 150 MPa @Temperature 25.0℃ 175 MPa @Temperature -100°C 250 MPa @Temperature -200 °C 140 - 180 MPa @Thickness 0.229- 25.4 mm |

179 MPa 165-205 MPa @Thickness 0.152 -4.11 mm |

200 MPa18.0 MPa @Temperature 400℃ 29.0 MPa @Temperature 300°C 96.0 MPa @Temperature 200°C 180 MPa @Temperature 100℃ 200 MPa @Temperature 25.0°C 210 MPa @Temperature -30.0 °C 230 MPa @Temperature -100°C 290 MPa @Temperature -200 °C =185 MPa @Thickness 0.152-3.25 mm |

105-130 MPa @Thickness 12.7 -50.8 mm 115-125 MPa @Thickness 6.35 -12.7 mm 100 - 150 MPa @Thickness 50.8-76.2 mm |

|

| Tensile Strength, Yield |

41.4 MPa 12.0 MPa @Temperature 400°C 17.0 MPa @Temperature 300 °C 30.0 MPa @Temperature 200°C 38.0 MPa @Temperature 100 °C 41.0 MPa @Temperature 25.0°C 45.0 MPa @Temperature -30.0°C 52.0 MPa @Temperature -100°C 60.0 MPa @Temperature -200°C >=34.0 MPa @Thickness 0.152-76.2 mm |

124 MPa >= 83.0 MPa @Thickness 0.432 - 50.8 mm |

145 MPa 12.0 MPa @Temperature 400°C 17.0 MPa @Temperature 300°C 62.0 MPa @Temperature 200°C 130 MPa @Temperature 100 °C 145 MPa @Temperature -30.0 C 145 MPa @Temperature 25.0 "℃ 155 MPa @Temperature -100 °C 170 MPa @Temperature -200°C >=115 MPa @Thickness 0.229 - 25.4 mm |

172 MPa >=145 MPa @Thickness 0.152-4.11 mm |

186 MPa12.0 MPa @Temperature 400°C 17.0 MPa @Temperature 300 "℃ 62.0 MPa @Temperature 200 ℃ 145 MPa @Temperature 100 °C 185 MPa @Temperature 25.0 °C 190 MPa @Temperature -30.0 ℃ 210 MPa @Temperature -100 ℃ 230 MPa @Temperature -200 °c >=165 MPa @Thickness 0.152-3.25 mm |

>=41.0 MPa @Thickness 12.7 -50.8 mm >=41.0 MPa @Thickness 50.8-76.2 mm >= 69.0 MPa @Thickness 6.35 - 12.7 mm |

|

|

Elongation at Break |

40 % @Temperature 25.0°C 41 % @Temperature -30.0 C 43 % @Temperature -100°C 43 % @Temperature 100°C 46 % @Temperature -200°C 60 % @Temperature 200°C 70 % @Temperature 300 °C 75 % @Temperature 400°C 14 - 25% @Thickness 0.152-76.2 mm 30 % @Thickness 1.59 mm 40 % @Diameter 12.7 mm |

3.0 - 10 % @Thickness 0.432 - 50.8 mm 10 % @Thickness 1.59 mm 20 % @Diameter 12.7 mm |

16 % @Temperature -30.0°C 16 % @Temperature 25.0°C 16 % @Temperature 100°C 19 % @Temperature -100°C 20 % @Temperature 200°C 30 % @Temperature -200°C 70 % @Temperature 300°C 75 % @Temperature 400°C 1.0- 10 % 2.0@Thickness 0.229-25.4 mm 8.0 % @Thickness 1.59 mm 16 % @Diameter 12.7 mm |

1.0 - 4.0 % @Thickness 0.152-4.11 mm 5.0 % @Thickness 1.59 mm 14 % @Diameter 12.7 mm |

10 % @Temperature -30.0°C 10 % @Temperature 25.0°C 10 % @Temperature 100 C 12 % @Temperature -100℃ 18 % @Temperature 200°C 23 % @Temperature -200 °C 70 % @Temperature 300°C 75 % @Temperature 400 ℃ 1.0 -4.0 % @Thickness 0.152-3.25 mm 4.0 % @Thickness 1.59 mm 10 % @Diameter 12.7 mm |

8.0 % @Thickness 6.35 -12.7 mm 12 % @Thickness 12.7 - 50.8 mm 18 % @Thickness 50.8-76.2 mm |

|

| Modulus of Elasticity | 68.9 GPa | 70.0 GPa | |||||

| Notched Tensile Strength | 110 MPa | 172 MPa | |||||

| Ultimate Bearing Strength | 207 MPa | 228 MPa | 241 MPa | 296 MPa | |||

| Bearing Yield Strength | 83.0 MPa | 131 MPa | 193 MPa | 262 MPa | |||

| Poissons Ratio | 0.33 | ||||||

| Fatigue Strength |

48.3 MPa @# of Cycles 5.00e+8 |

55.2 MPa @# of Cycles 5.00e+8 |

62.1 MPa @# of Cycles 5.00e+8 |

68.9 MPa @# of Cycles 5.00e+8 |

68.9 MPa @# of Cycles 5.00e+8 |

||

| Machinability | 10 % | 10 % | 30 % | 30 % | |||

| Shear Modulus | 25.0 GPa | ||||||

| Shear Strength | 75.8 MPa | 82.7MPa | 96.5MPa | 103MPa | 110MPa | ||

| Electrical Properties | Electrical Resistivity |

0.00000349 ohm-cm @Temperature 20.0 °C |

0.00000416 ohm-cm @Temperature 20.0 °C |

0.00000416 ohm-cm @Temperature 20.0 °C |

0.00000430 ohm-cm |

0.00000432 ohm-cm @Temperature 20.0 °C |

|

| Magnetic Susceptibility | 8.0e-7 | ||||||

| Thermal Properties | CTE, linear |

21.5 µm/m-°C @Temperature -50.0 - 20.0°C 23.2 µm/m-°C @Temperature 20.0 - 100°C 24.1 µm/m-°C @Temperature 20.0 - 200°C 25.1 µm/m-°C @Temperature 20.0 - 300°C |

21.5 µm/m-°C @Temperature -50.0 - 20.0°C 23.2 µm/m-°C @Temperature 20.0 - 100℃ 23.2 µm/m-°C @Temperature 20.0 - 100℃ 24.1 µm/m-°C @Temperature 20.0 - 200°C 25.1 µm/m-°C @Temperature 20.0 - 300°C |

21.5 µm/m-°C @Temperature -50.0 - 20.0 C 23.2 µm/m-°C @Temperature 20.0 - 100°C 24.1 µm/m-°C @Temperature 20.0 - 200°C 25.1 µm/m-°C @Temperature 20.0 - 300°C |

21.5 µm/m-°C @Temperature -50.0 - 20.0°C 23.2 µm/m-°C @Temperature 20.0 - 100℃ 24.1 µm/m-°C @Temperature 20.0 - 200℃ 25.1 µm/m-°C @Temperature 20.0 - 300°C |

21.5 µm/m-°C @Temperature -50.0 - 20.0°C 23.2 µm/m-°C @Temperature 20.0 - 100°C 24.1 µm/m-°C @Temperature 20.0 - 200°C 25.1 µm/m-°C @Temperature 20.0 - 300°C |

21.5 µm/m-°C @Temperature -50.0 - 20.0°C 23.2 µm/m-°C @Temperature 20.0 - 100°C 24.1 µm/m-°C @Temperature 20.0 - 200℃ 25.1 µm/m-°C @Temperature 20.0 - 300°C |

| Specific Heat Capacity | 0.893 J/g-°C | ||||||

| Thermal Conductivity | 193 W/m-K | 163 W/m-K | 159 W/m-K | 157 W/m-K | 154 W/m-K | ||

| Melting Point | 643 - 654 °C | ||||||

| Solidus | 643 °C | ||||||

| Liquidus | 654 °C | ||||||

| Processing Properties | Annealing Temperature | 413 °C | |||||

3003 aluminum discs use cold processing methods to improve their mechanical properties

- O(soft): In the annealed temper, it has high plasticity and high elongation

- H14 H24: Good plasticity, medium hardness, medium elongation.

- H18 H28: low plasticity, good corrosion resistance, good weldability, poor machinability, and low elongation.

Characteristics

Excellent elongation and tensile strength;

Good processing performance, high deep drawing and drawing performance;

Gas welding, hydrogen welding, resistance welding, brazing;

High plasticity, electrical conductivity, thermal conductivity;

Easy to withstand different pressure processing, extension, and bending;

Compared with steel, 3003 aluminum circles are lighter and less likely to rust.

3003 Aluminum disc annealing heat treatment process

Complete annealing:

Heating to 390~430℃; depending on the effective thickness of the material, the holding time is 30~120min; cooling in the furnace to 300℃ at a speed of 30~50℃/h, and then air cooling (natural cooling).

Rapid annealing:

Heating 350~370℃; depending on the effective thickness of the material, holding time 30~120min; air (natural cooling) or water cooling.

Quenching and aging:

quenching 500~510℃, air cooling (natural cooling); artificial aging 95~105℃, 3h, air cooling; natural aging at room temperature 120h

Weight and price calculation

The 3003 aluminum circle weight calculation formula: πR²*T*ρ

- π: Pi, the value is approximately 3.1415926;

- R: Radius of disc

- T: Thickness of disc

- ρ: The density of the aluminum disc, the value is usually 2.7 g/cm³

3003 aluminum circle price calculation formula: SME aluminum ingot spot price + processing fee + freight

- SME aluminum ingot spot price: SME A00 aluminum ingot price, updated at around 10:30 am daily.

- Processing fee: including site cost, labor cost, etc.

- Freight: The logistics cost of circles and disks can be selected according to different transaction terms.

Henan Xienuo supports three aluminum ingot prices: aluminum ingot prices for the day, aluminum ingot prices for the past three days, and aluminum ingot prices for the past five days. Leave us a message or send an inquiry directly.

Production technology

Production process

- Ingot/Master Alloys

- Melting Furnace

- Holding Furnace

- D.C. Caster

- Slab

- Scalper

- Hot Rolling Mill

- Cold Rolling Mill

- Punching

- Annealing Furnace

- Final Inspection

- Packing

- Delivery

Cutting process

| Thickness | Cutting process |

|---|---|

| Thickness | Cutting process |

| Less than 3.0 mm | The form of piercing blank feeding directly will be applied. |

| 3.0mm - 100mm | The bar cutting, laser cutting, CNC water cutting, and cutting will be used for blank feeding production. |

| Higher than 100mm | Aluminum bar sawing and direct production or forging |

Classification

- 3003 color-coated aluminum circle

- 3003 mirror aluminum disk

- 3003 forged aluminum discs

- 3003 deep-drawn aluminum circle

- 3003 aluminum tread circle plate

- 3003 aluminum diamond circle plate

- 3003 aluminum anodized circle plate

Applications

3003 aluminium circle has higher strength and corrosion resistance than the 1000-series such as 1060. It’s usually used in the production of cookware in the kitchen, such as utensils, non-stick pans/pots, bowls, or cups, and is also used in lamp, cart, signage, and building decoration materials.

Cookware: Cookware aluminium circles have extremely high requirements for hardness deep drawing performance and stable performance. The post-processing process includes an anodizing process, enamel process, spray painting, spray coating, and deep drawing; currently, it is mainly used in non-stick pans, pressure cookers, and other kitchen utensils.

Lamp accessories: Aluminum circles for lamps, aluminum discs for lampshades, lampshades for downlighting, laminate lights, street lights, and other common lighting applications.

Instruction sign: Aluminum circles for traffic road signs, used for road sign, billboards, etc.

Building materials: curtain wall panels, ceiling materials, decorative materials, etc.

Aluminum alloy is very light and durable, because there is no "rust" problem, and it looks more "pretty" than steel products. Cookware made of 3003 aluminum discs also has the characteristics of fast heat conduction and even heating.

What is the difference between 3003, 1060 and 1100 aluminum circles?

1060 and 3003 circles are very similar in application, such as making cookers and lamps, and their prices are similar. Many industry experts are not clear about the difference between the two. But we cannot let them continue to confuse us.

| Item | 1060 | 1100 | 3003 |

|---|---|---|---|

| Aluminum content and main alloying elements | 99.6% Pure aluminium | Aluminum content is approximately 99.00% | Aluminium content is about 98%, 1% to 1.5% manganese |

| density | 2.71 g/cm³ | 2.71 g/cm³ | 2.72 g/cm³ |

| Processing performance | High (suitable for deep drawing, stretching, bending, etc.) | Almost the same as 1060 | Processing performance is slightly weaker than 1060 |

| Corrosion resistance | Regular | Slightly stronger than 1060 | High |

| Strength | Regular | Higher than 1060 | High |

| Conductive properties | Powerful | Weaker than 1060 | Low |

| Welding performance | Weak | Weak | High |

| price | Good economy | Good economy | Regular |

Why choose us?

Henan Xienuo is a professional 3003 aluminium circle manufacturer. The factory is located in Gongyi City, Henan Province . The company has 16 casting and rolling production lines, 4 cold rolling mills, and 4 flattening machines. It provides various specifications of 3003 aluminum round sheet with short delivery time and high product quality. We Can provide customers with more satisfactory products and services.

Xienuo's 3003 aluminium disks have uniform grains and moderate grain sizes, ensuring excellent deep drawing and spinning performance, effectively avoiding drawing lines, ruffles, and high ear-making rates that may occur during post-processing. unpleasant sight;

Our customers are all over the world, and our products are exported to more than 40 countries such as Thailand, Vietnam, South Korea, Malaysia, Singapore, India, Bangladesh, Pakistan, Mexico, etc., Turkey, Saudi Arabia, Qatar, Poland, Sweden, etc.