Commonly used busbar materials include copper, aluminum, and steel. Commonly used busbar types include stranded steel core aluminum stranded wires (overhead wires), aluminum busbars and copper busbars, and tubular busbars.

In the power system, the busbar connects various current-carrying branch circuits in the power distribution device and plays the role of collecting, distributing and transmitting electrical energy. Xienuo can produce busbar such as aluminum busbar, tubular aluminum busbar and composite shielded insulated aluminum tubular busbar.

What is tubular aluminum busbar

Aluminum alloy tubular busbar also know as aluminum bus pipe tube, it is one of the main products of busbar and one of the key equipment in power transmission and transformation system. It plays a vital role in the safe and reliable operation of power transmission and transformation systems and power equipment.

Tubular aluminum busbar is a new conductor that replaces the traditional flat busbar, rod-shaped busbar and multi-strand steel core aluminum stranded wire. It is one of the key equipment in the power transmission and transformation system.

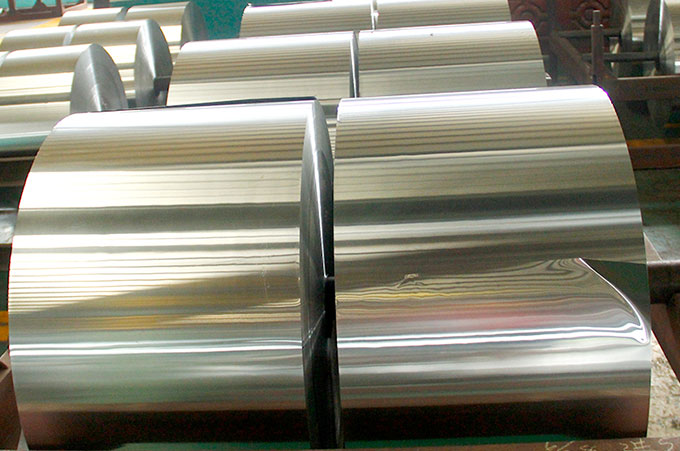

Electrical aluminum bus tube pipe is a hollow tube structure with glossy surface, beautiful appearance and uniform size.

The outer diameter of Xienuo's tubular busbar ranges from φ60mm to φ450mm, the wall thickness ranges from 3mm to 12mm. The length of a single busbar can be up to 15 meters according to customer needs. Check out our available sizes.

Xienuo's bus pipe tube Specification

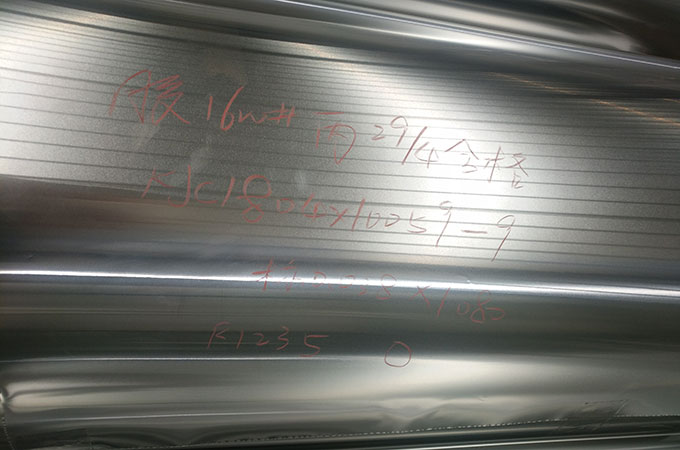

- Alloy:6063, 6061, 6101, 3A21, 3003, 1060, 1070

- Temper:T6 T61 T63 T64 T65 T7 H14 H18 O

- Outer diameter:Φ60mm-Φ450mm

- Wall thickness:3mm-15mm

- Length: The length of a single bus pipe can reach 15 meters;deviation:+15~+25mm

- Curvature:m/L < 2.0mm

- Surface requirement:The surface is smooth and flat, without cracks, wrinkles, inclusions, deformation, or distortion.

- Product requirement:The finished pipeline is completely straight; High dimensional accuracy and high tensile strength; Not prone to discharge and corona.

- Profiles can be provided:Certificate of origin; Invoice and PL certified by Chamber of Commerce; Test certificate according to EN 10204 3.1;

It complies with ASTM B241, ASTM B 317M-07, GB/27676-2011, GB/T 33228-2016, IS:5082, IS:2673etc. standards. It can also be customized according to customer needs.

Xienuo's hot selling aluminum bus pipe tube

- 6061 conductive aluminum bus tube pipe

- 6063 conductive aluminum bus tube pipe

- 6101 electrical tubular aluminum bus bar

- 1350 electrical tubular aluminum bus pipe

- 1060 1070 EC aluminum bus tube pipe

- 3003 3A21 aluminum tubular bus bar

Product advantages

- Xienuo's tubular bus bars use advanced hot rolling and reverse extrusion technology to produce seamless aluminum pipes with smooth surface, high precision, high tensile strength, and are not prone to discharge and deformation;

- The product has excellent processing, welding, electrical conductivity and heat resistance properties.

- Good convection heat dissipation conditions, low temperature rise, small loss, strong conductivity and large carrying capacity

- The installation area is small, and the combined pipe busbar occupies 1/3 of the flexible conductor area;

- Resistant to corrosion, not easily covered with ice, strong in disaster resistance, and long in service life;

- Easy to install, beautiful in appearance, safe, stable and reliable in operation, and easy to inspect and maintain.

Application

- Applied to conductors of HV substation & convertor station

- Applied to crossover tubular busbar

- Applied to outdoor busbar supports

- Applied to outdoor busbar suspension

- Applied to jumper wire connection

Chemical components

| Component | Contents | ||||||

|---|---|---|---|---|---|---|---|

| Elements | 1060 | 1070 | 1350 | 3A21 | 6061 | 6063 | 6101 |

| Silicon, Si | 0.25 | 0.2 | 0.1 | 0.6 | 0.20-0.6 | 0.3-0.7 | |

| Iron, Fe | 0.35 | 0.25 | 0.4 | 0.7 | 0.7 | 0.35 | 0.5 |

| Magnesium, Mg | 0.03 | 0.03 | 0.05 | 0.8-1.2 | 0.45-0.9 | 0.35-0.8 | |

| Zinc, Zn | 0.05 | 0.04 | 0.05 | 0.15 | 0.25 | 0.10 | 0.1 |

| Manganese, Mn | 0.03 | 0.03 | 0.01 | 1.0-1.6 | 0.15 | 0.03 | |

| Titanium, Ti | 0.03 | 0.03 | 0.01 | 0.10-0.2 | 0.15 | 0.10 | |

| Copper, Cu | 0.05 | 0.04 | 0.05 | 0.2 | 0.15-0.4 | 0.1 | 0.1 |

| Vanadium, V | 0.05 | 0.01 | |||||

| Chromium, Cr | 0.01 | 0.04-0.35 | 0.10 | 0.03 | |||

| Boron, B | 0.05 | 0.06 | |||||

| Aluminum, Al | >=99.6 | >=99.7 | >=99.5 | Remainder | Reminder | Remainder | Remainder |

Physical property

| Property | 6063G(6063) | LDRE(6R05) | 6101 | 3A21 | 1060 |

|---|---|---|---|---|---|

| Density (g/cm3)(20℃) | 2.75 | 2.75 | 2.7 | 2.73 | 2.7 |

| Melting point (℃) | 620~640 | 620~640 | 620~640 | 620~640 | 620~640 |

| Thermal conductivity(cal) | 0.5 | 0.51 | 0.5 | 0.46 | 0.5 |

| The relative conductivity IACS% | >=51 | >=56.5 | >=55 | >=41 | >=60 |

| Poisson's Coefficient μ | 0.315 | 0.317 | 0.313 | 0.3 | 0.31 |

| Temperature coefficient of resistance at 20℃ | 0.0041 | 0.0041 | 0.0041 | 0.0041 | |

|

Temperature linear expansion coefficient (1/℃)(20~100℃) |

23.4×10-6 | 24.7×10-6 | 23.6×10-4 | 23.5×10-6 | 23.5×10-6 |

| Resistivity at 20℃ (ρ, Ω·mm2/m) | 0.034 | 0.031 | 0.031 | 0.043 | 0.029 |

| Elasticity modulus (MPa) | 69000 | 69000 | 69000 | 70000 | 70000 |

| Maximum allowable working temperature | 200℃ | 200℃ | 200℃ | 200℃ | 200℃ |

Mechanical property

| Alloy designation | Temper | Mechanical Property | |||||

|---|---|---|---|---|---|---|---|

| Tensile strength (Mpa) | Yield strength (Mpa) | Elongation (%) | |||||

| Standard value | Measured value | Standard value | Measured value | Standard value | Measured value | ||

| 6063G(6063) | T10 | >=180 | >=195 | >=160 | >=170 | — | >=12 |

| T6 | >=205 | >=220 | >=175 | >=190 | >=8 | >=12 | |

| LDRE(6R05) | T10 | >=185 | >=200 | >=165 | >=175 | — | >=12 |

| T6 | >=210 | >=225 | >=180 | >=200 | >=8 | >=12 | |

| 6101 | T6 | >=200 | >=215 | >=170 | >=185 | >=10 | >=12 |

| 6061 | T6 | >=260 | >=285 | >=240 | >=255 | >=8 | >=9 |

| 3A21/3003 | H14 | >=135 | >=145 | >=110 | >=120 | >=12 | >=12 |

| 1060 | H18 | >=150 | >=160 | >=130 | >=145 | >=8 | >=9 |

Geometric Parameters

| Size (mm) | Cross Section (mm) | SectionFactor (cm) | RadiusofInertia (cm) | MomentofInertia (cm) |

|---|---|---|---|---|

| Ф80/72 | 954.56 | 17.61 | 2.69 | 69.11 |

| Ф80/70 | 1177.50 | 21.19 | 2.66 | 83.16 |

| Ф100/92 | 1205.76 | 28.36 | 3.40 | 139.14 |

| Ф100/90 | 1491.50 | 34.39 | 3.36 | 168.73 |

| Ф100/80 | 2826.00 | 59.04 | 3.20 | 289.67 |

| Ф110/100 | 1648.50 | 42.19 | 3.72 | 227.70 |

| Ф110/98 | 1959.36 | 49.25 | 3.68 | 265.79 |

| Ф120/110 | 1805.50 | 50.79 | 4.07 | 299.04 |

| Ф120/108 | 2147.76 | 59.43 | 4.04 | 349.87 |

| Ф120/100 | 3454.00 | 89.47 | 3.91 | 526.74 |

| Ф130/116 | 2703.54 | 80.42 | 4.36 | 512.93 |

| Ф130/114 | 3064.64 | 89.78 | 4.32 | 572.63 |

| Ф130/110 | 3768.00 | 107.08 | 4.26 | 682.95 |

| Ф130/100 | 5416.50 | 142.78 | 4.10 | 910.65 |

| Ф150/136 | 3143.14 | 109.43 | 5.06 | 805.35 |

| Ф150/134 | 3567.04 | 122.55 | 5.03 | 901.93 |

| Ф150/130 | 4396.00 | 147.09 | 4.96 | 1082.52 |

| Ф160/140 | 4710.00 | 132.70 | 5.32 | 1331.00 |

| Ф170/156 | 3582.74 | 142.92 | 5.77 | 1192.07 |

| Ф170/154 | 4069.44 | 160.45 | 5.73 | 1338.24 |

| Ф170/150 | 5024.00 | 193.51 | 5.67 | 1613.96 |

| Ф180/164 | 4320.64 | 181.31 | 6.09 | 1601.23 |

| Ф180/160 | 5338.00 | 219.11 | 6.02 | 1935.03 |

| Ф200/184 | 4823.04 | 226.89 | 6.79 | 2226.32 |

| Ф200/180 | 5966.00 | 275.12 | 6.73 | 2699.62 |

| Ф250/230 | 7536.00 | 443.14 | 8.49 | 5435.34 |

| Ф250/226 | 8967.84 | 519.00 | 8.43 | 6365.82 |

| Ф280/256 | 10098.24 | 661.28 | 9.48 | 9084.38 |

| Ф300/280 | 9106.00 | 651.15 | 10.26 | 9584.07 |

| Ф300/276 | 10854.84 | 765.74 | 10.19 | 11270.72 |

| Ф300/270 | 13423.50 | 928.53 | 10.09 | 13666.80 |

| Ф320/296 | 11605.44 | 877.87 | 10.90 | 13782.62 |

| Ф350/326 | 12735.84 | 1060.47 | 11.96 | 18210.34 |

| Ф350/320 | 15778.50 | 1291.57 | 11.86 | 22178.65 |

| Ф350/330 | 10676 | 680.8 | 12.02 | 15440 |

| Ф400/380 | 12246 | 895.7 | 13.79 | 23298 |

| Ф450/436 | 9737.14 | 808.9 | 15.7 | 23894 |

| Ф450/430 | 13816 | 1140 | 15.6 | 33452 |

Remarks:The above is regular sizes, we can manufacture busbars with similar specifications as per user's requirements.

Carrying Capacity(Ambient Temperature at 20℃)

| Size (mm) | Carrying Capacity (mm) | |||||

|---|---|---|---|---|---|---|

| Size(mm) | 6063 | LDRE | 6101 | |||

|

Temperature Rise 70℃ |

Temperature Rise 80℃ |

Temperature Rise 70℃ |

Temperature Rise 80℃ |

Temperature Rise 70℃ |

Temperature Rise 80℃ |

|

| Ф80/72 | 2112 | 2259 | 2153 | 2304 | 2191 | 2344 |

| Ф80/70 | 2345 | 2509 | 2392 | 2558 | 2433 | 2603 |

| Ф100/92 | 2547 | 2729 | 2598 | 2783 | 2643 | 2831 |

| Ф100/90 | 2833 | 3035 | 2889 | 3095 | 2940 | 3149 |

| Ф100/80 | 3900 | 4178 | 3977 | 4260 | 4046 | 4334 |

| Ф110/100 | 3074 | 3295 | 3135 | 3360 | 3189 | 3418 |

| Ф110/98 | 3351 | 3592 | 3418 | 3663 | 3477 | 3727 |

| Ф120/110 | 3311 | 3550 | 3376 | 3621 | 3435 | 3684 |

| Ф120/108 | 3611 | 3872 | 3682 | 3949 | 3746 | 4018 |

| Ф120/104 | 4133 | 4432 | 4215 | 4520 | 4288 | 4598 |

| Ф120/100 | 4579 | 4911 | 4670 | 5008 | 4751 | 5095 |

| Ф130/116 | 4159 | 4462 | 4242 | 4551 | 4315 | 4630 |

| Ф130/114 | 4428 | 4751 | 4516 | 4845 | 4594 | 4929 |

| Ф130/110 | 4910 | 5268 | 5007 | 5372 | 5094 | 5466 |

| Ф130/100 | 5887 | 6316 | 6004 | 6441 | 6108 | 6553 |

| Ф140/130 | 3772 | 4050 | 3847 | 4130 | 3914 | 4201 |

| Ф140/124 | 4719 | 5065 | 4812 | 5165 | 4896 | 5255 |

| Ф140/120 | 5235 | 5620 | 5339 | 5731 | 5432 | 5831 |

| Ф150/136 | 4701 | 5048 | 4794 | 5148 | 4877 | 5238 |

| Ф150/134 | 5008 | 5378 | 5107 | 5485 | 5196 | 5580 |

| Ф150/130 | 5559 | 5970 | 5670 | 6089 | 5768 | 6194 |

| Ф160/148 | 4617 | 4960 | 4708 | 5059 | 4790 | 5146 |

| Ф160/140 | 5883 | 6320 | 5999 | 6445 | 6103 | 6557 |

| Ф170/156 | 5236 | 5628 | 5340 | 5739 | 5432 | 5839 |

| Ф170/154 | 5580 | 5998 | 5691 | 6116 | 5790 | 6223 |

| Ф170/150 | 6200 | 6664 | 6323 | 6796 | 6433 | 6914 |

| Ф180/168 | 5107 | 5491 | 5208 | 5600 | 5299 | 5697 |

| Ф180/164 | 5863 | 6304 | 5980 | 6429 | 6083 | 6541 |

| Ф180/160 | 6517 | 7007 | 6646 | 7146 | 6762 | 7270 |

| Ф200/188 | 5592 | 6017 | 5703 | 6136 | 5802 | 6242 |

| Ф200/184 | 6424 | 6911 | 6551 | 7048 | 6665 | 7171 |

| Ф200/180 | 7144 | 7687 | 7286 | 7839 | 7412 | 7975 |

| Ф250/238 | 6781 | 7306 | 6915 | 7451 | 7035 | 7580 |

| Ф250/234 | 7797 | 8402 | 7952 | 8568 | 8090 | 8717 |

| Ф250/230 | 8682 | 9355 | 8854 | 9540 | 9007 | 9706 |

| Ф250/226 | 9471 | 10205 | 9658 | 10407 | 9826 | 10588 |

| Ф280/256 | 10456 | 11275 | 10663 | 11499 | 10848 | 11698 |

| Ф300/280 | 10180 | 10982 | 10381 | 11200 | 10561 | 11394 |

| Ф300/276 | 11113 | 11989 | 11333 | 12227 | 11530 | 12439 |

| Ф300/270 | 12359 | 13334 | 12604 | 13598 | 12823 | 13834 |

| Ф320/296 | 11757 | 12690 | 11990 | 12942 | 12198 | 13166 |

| Ф320/290 | 13081 | 14119 | 13340 | 14398 | 13571 | 14648 |

| Ф350/330 | 11650 | 12582 | 11881 | 12831 | 12087 | 13054 |

| Ф350/326 | 12724 | 13743 | 12976 | 14015 | 13202 | 14258 |

| Ф350/320 | 14163 | 15296 | 14444 | 15599 | 14694 | 15870 |

| Ф400/380 | 13099 | 14161 | 13359 | 14441 | 13591 | 14692 |

| Ф450/436 | 12201 | 13200 | 12443 | 13462 | 12659 | 13696 |

| Ф450/430 | 14534 | 15724 | 14822 | 16035 | 15079 | 16314 |

Available specification

| Nominal O/D (mm) | Wall thickness (mm) | Length (m) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 4.0 | 5.0 | 6.0 | 7.0 | 8.0 | 9.0 | 10.0 | 12.0 | 15.0 | 18.0 | ||

| 80 | √ | √ | <=13 | ||||||||

| 90 | √ | √ | √ | √ | <=13 | ||||||

| 100 | √ | √ | √ | √ | √ | √ | √ | <=13 | |||

| 110 | √ | √ | √ | √ | √ | √ | √ | <=13 | |||

| 120 | √ | √ | √ | √ | √ | √ | <=13 | ||||

| 130 | √ | √ | √ | √ | √ | √ | <=13 | ||||

| 150 | √ | √ | √ | √ | √ | <=13 | |||||

| 170 | √ | √ | √ | √ | √ | <=13 | |||||

| 200 | √ | √ | √ | <=13 | |||||||

| 250 | √ | √ | √ | √ | √ | √ | √ | <=13 | |||

| 280 | √ | √ | √ | <=13 | |||||||

| 300 | √ | √ | √ | √ | <=12 | ||||||

| 320 | √ | √ | <=11 | ||||||||

| 350 | √ | √ | √ | <=10 | |||||||

| 400 | √ | √ | √ | <=10 | |||||||

| 450 | √ | √ | √ | <=10 | |||||||

|

Note:“√”refers to available scope, other specifications can be consulted with each other if necessary. |

|||||||||||

Power Fitting

- Grounding clamps

- Grounding Rod

- copper/aluminium connecting terminals

- Tubular Bus-bar Supports

- Bus-bar Supports

- Tubular Bus-bar End Supports

- Suspension Supports for Tubular Bus-bar

- T-Connectors for Tubular Bus-bar

- Terminal connectors For Horizontal Tubular Bus-bar

- Single Flexible Jumper Clamps

- Flexible Terminal Connectors for Tubular Bus-bar

- Flexible Clamps for Tubular Bus-bar

- End-caps

- Jumping Clamps

- Crossing Bus-bar Transition Fittings

- Y-Connectors for 3-2 Bundle Conductor

- Vertical Bus-bar Supports