What is color color-coated aluminum coil?

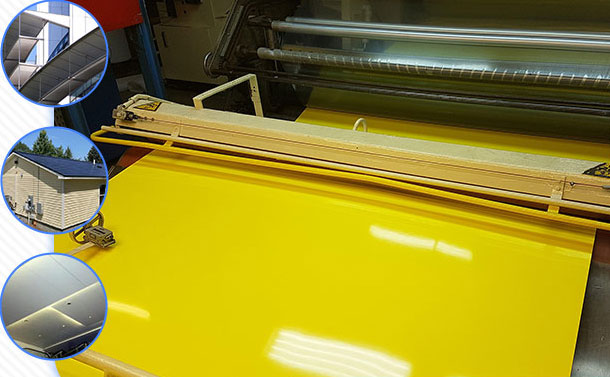

Color-coated aluminum coils are also called colored aluminum coils. Color-coated aluminum sheets are produced by cutting color-coated aluminum coils with shearing equipment, or by spraying plain aluminum sheets. Color-coated aluminum strips are produced by slitting color-coated aluminum coils with slitting equipment.

Color-coated aluminum coils are aluminum coils that are coated with paint coatings of various colors on the surface after cleaning, chromating, roller coating, baking, and other processing techniques.

Color-coated aluminum coils and sheets are used in the construction industry, interior decoration, electronic product casings, road signs, and other fields.

Xienuo’s hot-selling color-coated aluminum coils

Xienuo provides PVDF coating, PE coating, epoxy paint-coated aluminum coil, HDP coating, HDPE coating, PVC aluminum coil and sheet, and other products. The coating colors can be selected, up to hundreds of kinds, and the minimum order quantity is small, the advantages of low price and short delivery time.

Xienuo's coating system can also be combined with special coating technologies, such as antistatic, antibacterial, metallic appearance, printing coatings, etc. In addition, it can also provide subsequent processing such as flattening, slitting, and profiling.

Alloys: 1000, 3000, and 5000 series aluminum coils, such as:

- 1050 color coated aluminum coil and sheet,

- 1060 color coated aluminum coil and sheet

- 1070 color coated aluminum coil and sheet

- 3003 color coated aluminum coil and sheet

- 3004 color coated aluminum coil and sheet

- 3105 color coated aluminum coil and sheet

- 5005 color coated aluminum coil and sheet

- 5052 color coated aluminum coil and sheet

Xienuo can also customize the production of color-coated aluminum coils coated with fluorocarbon on one side and polyester on the other side; or color-coated aluminum coils coated with fluorocarbon on both sides.

Paint coating thickness:

- Single coating (4-20 microns)

- Double coating (25-28 microns)

- Triple coating (35-38 microns)

Customizable specifications:

- Coating: PE, PVDF, HDP, HDPE, PVC

- Coating brands: NIPPON, PPG, AKZONOBEL

- Aluminum coil thickness: 0.2mm-6.00mm

- Standard width: 1000-1250mm

- Special width: 50mm-1700mm

- Core diameter: 150mm, 405mm, 500mm, 505mm, 510mm

- Coating thickness: POLYESTER ≥18micron

- Glossiness: 10-90%

- Coating hardness: greater than 2H

- Adhesion: no less than level 1

- Impact resistance: 50kg/cm without paint peeling or cracks

- Colors: Up to hundreds, can be adjusted according to RAL and Pantone international color cards or customer samples.

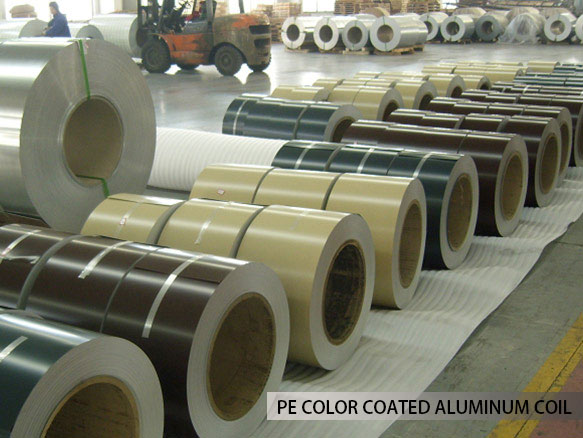

PE(polyester) color coated aluminum coil and sheet

After the surface of the aluminum coil is baked and painted multiple times, the polyester-coated aluminum coil formed on the surface of the aluminum coil is called a polyester color-coated aluminum coil.

PE (Polyester) is an anti-UV coating that not only has protective and decorative properties but also has good gloss and smoothness, which increases the corrosion resistance and durability of items. It is especially suitable for interior decoration and advertising boards.

PVDF(fluorocarbon) color coated aluminum coil and sheet

Fluorocarbon coating refers to PVDF resin, which generally refers to coatings made from homopolymers of vinylidene fluoride or copolymers of vinylidene fluoride and different small amounts of fluorinated vinyl monomers.

Fluorocarbon color-coated aluminum coils have good gloss, wear resistance, weather resistance, and no color difference. In harsh climates and environments, they have longer-lasting fading resistance and UV resistance than PE-coated aluminum coils. The service life reaches more than 20 years.

Fluorocarbon coatings can be divided into two categories based on their floor film-forming structures: ordinary fluorocarbon coatings and nano-fluorocarbon coatings.

Fluorocarbon color-coated aluminum coils are particularly suitable for indoor and outdoor decoration in public places, decoration and display of chain enterprises, exhibitions, etc., such as roof corrugated panels, fireproof veneer panels, aluminum ceilings, blinds, rolling shutters, garage doors, lighting, furniture, electronic appliances, and other different places.

Performance parameters

- Front coating thickness requirements: primer 5 microns, top paint 20-22 microns

- Back coating thickness recommended: primer 5 microns, top paint 5 microns

- Gloss: Standard 25±5

- Grid adhesion: No paint off

- T bend: 1T bending, no paints off

- Reverse impact: 9J paints, no paints off

- Pencil hardness: ≥HB (505 roller steel coating hardness test pencil )

- Organic Solvent resistance: Butanone MEK wipes 100 times, no paint breakage

- Scratch resistance: Probe scratch meter test weight 1000 grams, no paint breakage

- Humidity and heat resistance: Non-condensing humidity and heat test chamber is placed for 1000 hours, no bubbles, cracks, breakage, color, gloss, hardness variety

- Acid and alkali resistance: 5% hydrochloric acid soaking for 24 hours, no significant changes in appearance, after soaking in 5% sodium oxy oxide for 24 hours, there was no obvious change in appearance

- Boiling water resistance: 100°boiling water bath for 2 hours, no loss of light, discoloration, cracking, foaming, falling off and other phenomena

- Neutral salt spray test: 1000 hours, foaming grade < 2S3, no other obvious defects

- UV lamp accelerated aging test: OUVA-340 UV lamp test chamber 2000 hours of light, powder ≤ 1 level, no bubbling, cracking and other defects

- (if assessed according to the ASTM D4214 method, pulverization is not less than grade 8)

- Coating thickness: PVDF (fluorocarbon) ≥25micron

- Color and color difference: The color difference between the single-color coating and the standard color sheet is ΔEab* ≤ 1.5, and the color difference between the same batch of products is ΔEab* ≤ 1.5.

- Wear resistance: After the falling sand test, the wear coefficient should be ≥1.6 L/µm.

- Adhesion: The dry, wet, and boiling water adhesion of the coating should reach level 0

HDP color coated aluminum coil

HDP aluminum coil is a type of coated aluminum coil product, where HDP stands for High Durable Polyester. HDP aluminum coil has excellent weather resistance and corrosion resistance, making it suitable for applications in indoor and outdoor building decoration, advertising signs, home appliances, and other fields.

Performance parameters

- Dry film thickness front requirements: primer 5 microns, top paint 20-22 microns

- Recommended on the back: primer 5 microns, back paint 5 microns

- Gloss: 35± gloss can be provided. We also can provide other gloss according to customer requirements

- Grid adhesion: Paint film does not fall off

- T-bend: 3T paint film without shedding

- Reverse impact: 9J paint film does not fall off

- Pencil hardness: ≥2H(505 roll steel coating hardness test pencil

- Organic solvent resistance: butanone MEK wipe 100 times, no damage to the film

- Scratch resistance: The weight of the probe scratch tester is 1800 grams, and the paint film is not broken

- Humidity and heat resistance: The non-condensing humidity and heat test chamber is placed for 1000 hours.

- no bubbles. cracks, paint film peeling, no color, luster and hardness changes

- Acid and alkali resistance: 5% hydrochloric acid soaking for 24 hours, no significant changes in appearance,after soaking in 5% sodium oxy oxide for 24 hours, there was no obvious change in appearance

- Boiling water resistance: 100°boiling water bath for 2 hours, no loss of light, discoloration, cracking, foaming, falling off, and other phenomena

- Acid and alkali resistance: neural salt spray test 1000 hours, foaming grade < 2S3, no other obvious defects

- UV lamp acceleration: OUVA-340 UV lamp test chamber 2000 light hours, powder < 1 level, no blistering, cracking, other defects

- (if assessed according to the ASTM D4214 method, pulverization is not less than grade 8)

HDPE color coated aluminum coil

HDPE is the abbreviation of High-Density Polyethylene. The coating of HDPE color-coated aluminum coils uses high-density polyethylene resin as the base material. It is processed by a professional coating process to form a uniform and smooth coating.

This coating has good weather resistance and can resist the erosion of ultraviolet rays, oxidation, rain, and other external environmental factors, maintaining the long-term beauty of the aluminum coil.

Imitation stone coated aluminum coil

The imitation stone grain roller-coated aluminum sheet is light in weight. For the same area, the mass of the aluminum veneer is about 1/10 - 1/12 of that of brick wall painting, and 1/15 of the quality of dry-hanging marble and granite curtain walls. It is 15-1/7 that of concrete siding.

The imitation stone grain roller-coated aluminum sheet is a new decorative material based on the aluminum veneer, which is processed through a special roller coating or spraying process to give the aluminum veneer a strong stone three-dimensional effect, which is extremely realistic.

Common stone grain aluminum coils include marble grain aluminum coils and sheets, granite grain aluminum coils and sheets

Wood grain aluminum coil

The wood grain aluminum sheet is coated with a wood grain decorative coating on the surface of the aluminum sheet through spraying, heat transfer, or roller coating. The wood grain on the surface has clear filamentous fine lines or rough simulated wood grain texture. It is rich in color and natural and is an excellent building decoration material.

Imitation wood grain aluminum veneer does not contain formaldehyde, is non-toxic, and does not release harmful gases, so you no longer have to worry about the odor and physical harm caused by paint and glue substances after decoration.

Mirror color coated aluminum coil

The color-coated mirror aluminum coils use 1100, 3003, 3105, and other series of high-purity aluminum-based coils to ensure that the aluminum purity is above 99.8%, the mirror reflectivity is above 85%, and the clarity is above 94%.

| Item | Value | Tolerance |

|---|---|---|

| Thickness(mm) | 0.20-0.80 | ±0.02 |

| Width(mm) | Below 1600 | ±2 |

| Reflectance | ≥85% | ±1 |

| Diffuse reflectance | <20 | ±0.5 |

| Direct reflectance | >80 | ±1 |

| Degree of imaging | 92 | ±2 |

PVC coated aluminum trim coil

PVC-coated aluminum trim coils are aluminum trim coil coated with PVC material. They are beautiful, durable, and easy to clean. They are widely used in architectural decoration, furniture manufacturing, and other fields.

Features:

- Beautiful

- Durable

- Easy to clean

- Easy to process

- Environmental protection

PVC-coated aluminum trim coils are widely used in architectural decoration, furniture manufacturing, and other fields, such as decorative materials for building exterior walls, interior decoration, doors and windows, and coating materials for furniture, cabinets, and other products.

PVDF coating vs Polyester coating

The paint preparation and processing cycle of PVDF coating is longer than that of PE coating, so the delivery time of PVDF-coated aluminum coil is later than that of PE-coated aluminum coil.

A detailed comparison between PVDF coatings and polyester coatings, highlighting their differences in chemical composition, durability, color and gloss retention, environmental impact, application, cost, and maintenance.

| Feature | PVDF Coating | Polyester Coating |

|---|---|---|

| Chemical Composition | Contains PVDF resin, known for its exceptional chemical resistance and durability | Contains polyester resin, which is less chemically resistant and durable compared to PVDF |

| Durability | Highly durable, with excellent resistance to UV radiation, chemicals, and weathering | Moderately durable, with good UV resistance but less resistant to chemicals and weathering |

| Color Retention | Excellent color retention, maintains vibrant colors for an extended period | Good color retention, but may fade or chalk over time, particularly in harsh conditions |

| Gloss Retention | Maintains high gloss and sheen over time, making it suitable for architectural aesthetics | May experience gloss reduction over time, particularly in harsh outdoor environments |

| Environmental Impact | Generally more environmentally friendly due to longer lifespan and reduced maintenance | May require more frequent repainting or refinishing, resulting in a greater environmental impact |

| Applications | Widely used in architectural cladding, metal roofing, curtain walls, and high-end outdoor applications | Suitable for general-purpose applications such as appliances, automotive parts, and indoor equipment |

| Cost | Typically higher initial cost due to superior durability and performance | Lower initial cost but may require more maintenance and repainting over time, leading to higher long-term costs |

| Maintenance | Requires minimal maintenance and offers long-term cost savings | May require more frequent repainting or refinishing, leading to higher maintenance costs |

Coating process

Color coating pre-treatment

Before the color-coated aluminum coils and sheets are colored, the plain aluminum coils need to be further processed to make the aluminum coils have better coloring effects.

- Hot water cleaning

- Hot alkali degreasing

- Passivation treatment

Roller coating vs. spray coating

The coating processes for color-coated aluminum coils and aluminum sheets include roller coating and spray coating.

Roller coating refers to the continuous and uninterrupted degreasing, chemical pretreatment, and color coating of aluminum substrates.

Spraying uses the negative pressure generated by compressed air at the spray gun nozzle to spray the paint in the paint container from the paint nozzle to paint the aluminum sheet.

| Feature | Roller coating | Spray coating |

|---|---|---|

| Number of layers that can be coated | Front coating, color display coating | Front coating |

| Primer, the coating between the front coating and the aluminum sheet | ||

| Back coating, anti-corrosion coating on the back of aluminum sheet | ||

| Bake | Twice baked | Bake once |

| Coating film thickness | Uniform thickness | Relatively uneven |

| Color difference | Basically no color difference | Easy to age and appear color difference |

| Supportable experiments | Impact test, cross-hatch test, T value test, solvent resistance test, aging resistance test | Impact test, etc. |

Application of color-coated aluminum coils

Typical application

- Aluminum plastic panel

- Honeycomb panel

- Insulation board

- Aluminum curtain wall

- Blinds

- Roller shutters

- Aluminum magnesium manganese roofing system

- Aluminum ceiling

- Home appliance panel

- Downspouts

- Aluminum trim coil

Application advantages

- Various colors and strong decorative properties

- Good mechanical properties and ease of use

- Aging resistance and good weather resistance

- Economical, environmentally friendly and recyclable

Why choose us

Xienuo is a professional manufacturer of color-coated aluminum coil strips and sheets. We strictly implement the production standards required by customers, such as ASTM-B-209M, BS EN 485-2, BS EN 573-3, GB/T3880-2008 and other processing Production. We have a strict quality control system and product testing system to ensure that products leave the factory with zero defects.

Xienuo's testing includes:

- 30% sodium hydroxide test

- 30% hydrochloric acid test

- MEK Test

- T-shaped bending test

- Boiling test

- Pencil hardness test

- Impact and cross-cut testing

- Film thickness test