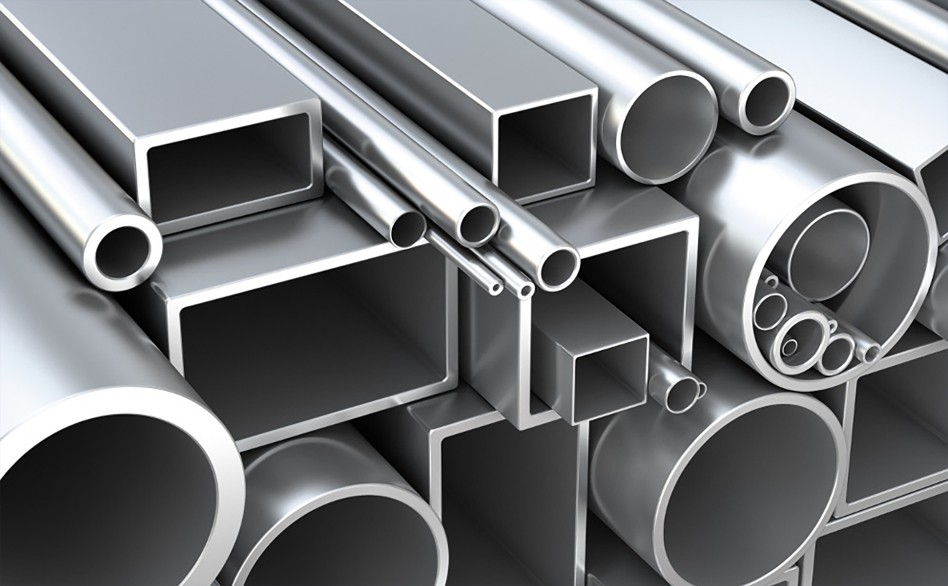

Aluminum Tube for Sale

Xienuo's hot-selling aluminum tubes include 1050, 1060, 2014, 2017, 2024, 2A12, 2219, 3003, 5052, 5083, 5086, 6005, 6105, 6041, 6061, 6082, 6162, 7075, etc.

1000 series aluminum tube

- 1050 aluminum tube

- 1060 aluminum tube

- 1070 aluminum tube

2000 series aluminum tube

- 2014 aluminum tube

- 2017 aluminum tube

- 2024 aluminum tube

- 2A12 aluminum tube

- 2219 aluminum tube

- 2A11 aluminum tube

- 2A14 aluminum tube

- 2A50 aluminum tube

3000 series aluminum tube

- 3003 aluminum tube

- 3A21 aluminum tube

5000 series aluminum tube

- 5052 aluminum tube

- 5083 aluminum tube

- 5086 aluminum tube

- 5154 aluminum tube

- 5454 aluminum tube

- 5456 aluminum tube

6000 series aluminum tube

- 6005 aluminum tube

- 6105 aluminum tube

- 6041 aluminum tube

- 6042 aluminum tube

- 6061 aluminum tube

- 6351 aluminum tube

- 6082 aluminum tube

- 6162 aluminum tube

- 6262 aluminum tube

- 6064 aluminum tube

- 6063 aluminum tube

- 6066 aluminum tube

- 6A02 aluminum tube

7000 series aluminum tube

- 7050 aluminum tube

- 7075 aluminum tube

- 7178 aluminum tube

Hot selling specifications

- Φ25×6

- Φ30×4

- Φ32×2.7

- Φ37×11

- Φ38×8

- Φ43×14

| Alloy | Shape | Size(mm) | Temper | Inventory(mm) |

|---|---|---|---|---|

|

1000 series, 2000 series, 3000 series, 5000 series, 6000 series, 7000 series, |

Aluminum round tube and pipe | Outer diameter: 4-300 | O, H12, H14, H22, H24, H32, H34, H38, H111, H112, T3, T351, T4, T451, T6, T651, T6511, T7351 | Inventory is changing, please contact us |

| Wall thickness: 0.25-40 | ||||

| Square aluminum tube | Side length: 4-300 | Inventory is changing, please contact us | ||

| Wall thickness: 0.25-40 | ||||

| Aluminum rectangular tubing | Side length: 4-300 | Inventory is changing, please contact us | ||

| Wall thickness: 0.25-40 | ||||

| Special-shaped pipe |

Customized according to drawings Wall thickness: 0.25-60 |

No stock available | ||

| The wall thickness and outer diameter of thin-walled round aluminum tubes are mostly around 20 to 130 mm, and the outside diameter of thick-walled round aluminum tubes are mostly around 15 to 160 mm. | ||||

Difference between aluminum pipe and tube

What are the differences between pipe and tube? Even industry experts may not really understand the difference between pipe and tube. However, for buyers or business owners, this is something that must be clarified, because understanding the difference between pipe and tube directly affects Our final purchasing decision is to reduce costs and increase efficiency.

The biggest difference between aluminum pipe and tube is the shape, followed by different measurement standards and applications.

What is aluminum pipe?

A pipe is a vessel. The cross-section is always circular. It is used to transport products, including fluids, gases, particles, powders, etc. The processing method of Aluminum pipe is relatively simple and easy. It generally uses a welding process and cannot be bent.

The most important dimensions for a pipe is the outer diameter (OD) together with the wall thickness (WT). OD minus 2 times WT (schedule) determine the inside diameter (ID) of a pipe, which determines the liquid capacity of the pipe .

What is aluminum tube?

A tube is structural, the cross section can be circular, square, rectangular, oval, seamless tube can be bent. Tubes are used in structural applications. Typically used where small diameters are required.

Tubes are indicated with outer diameter and wall thickness, in inches or in millimeters.

Summary

| Pipe | Tube | |

|---|---|---|

| Shape | Round | Round, square, oval, rectangular, etc. |

| Key Dimensions (Pipe and Tube Size Chart) | The most important dimensions for a pipe is the outer diameter (OD) together with the wall thickness (WT). OD minus 2 times WT (SCHEDULE) determine the inside diameter (ID) of a pipe, which determines the liquid capacity of the pipe. The NPS does not match the true diameter, it is a rough indication | The most important dimensions for a steel tube are the outside diameter (OD) and the wall thickness (WT). These parameters are expressed in inches or millimeters and express the true dimensional value of the hollow section. |

| Wall Thickness | The thickness of a aluminum pipe is designated with a "Schedule" value (the most common are Sch. 40, Sch. STD., Sch. XS, Sch. XXS). Two pipes of different NPS and same schedule have different wall thicknesses in inches or millimeters. | The wall thickness of a aluminum tube is expressed in inches or millimeters. For tubing, the wall thickness is measured also with a gage nomenclature. |

| Measure | Measured by nominal outside diameter (also known as NPS or nominal pipe size) and wall thickness. | It is measured by accurate outer diameter (OD) and wall thickness. Generally with more stringent tolerances and specifications. |

| Scalability | Tube can be scaled. | |

| Rigidity | Pipe is rigid and cannot be formed without special equipment. | It can be shaped through some efforts. The tubing will not be excessively deformed, wrinkled or broken when bent and coiled. |

| Strength | Pipe is less powerful than tube. | Stronger for applications requiring durability and strength. |

| Processing technology | Mainly obtained by welding process | Mainly obtained by extrusion and reverse extrusion process |

| Prise | Cheap | Higher price |

| End Connections | The most common are beveled, plain and screwed ends | Threaded and grooved ends are available for quicker connections on site |

Classification method of aluminum tubing

According to the shape: square aluminum tube, aluminum round tube, rectangular aluminum tube, oval aluminum tube, aluminum octagon tubing, special-shaped aluminum tube.

According to the extrusion process: seamless aluminum tubes and seamed aluminum tubes (ordinary extruded aluminum tubes). Seamless aluminum tubes can also be divided into hot-rolled seamless aluminum tubes, cold-rolled seamless aluminum tubes, and cold-drawn seamless aluminum tubes. tube, extruded seamless aluminum tube, etc.

According to accuracy: ordinary aluminum tubes and precision aluminum tubes. Precision aluminum tubes generally need to be reprocessed after extrusion, such as cold drawing, fine drawing, and rolling.

According to thickness: ordinary aluminum tube and thin-walled aluminum tube.

According to diameter: small diameter aluminum tubing and large diameter aluminum tube and pipe

Two surface treatment processes for aluminum tube

Chemical treatment: Anodizing, electrophoretic coating, fluorocarbon spraying, powder spraying, wood grain transfer

Mechanical treatment process: mechanical drawing, mechanical polishing, sandblasting

Aluminum tube processing technology

Seamless aluminum tube VS seamed aluminum tube

According to the production process of aluminum pipes, aluminum pipes are divided into seamed aluminum pipes and seamless aluminum pipes. Their uses and characteristics are different.

Seamless aluminum tube and pipe: It is a high-strength aluminum alloy material produced by reverse extrusion (indirect extrusion) after perforating aluminum rods. Seamless aluminum tube has the characteristics of small specific gravity, easy processing, and high mechanical strength.

Seamed aluminum pipe: They have the characteristics of relatively simple production, various shapes, and complete specifications. The disadvantage of seamed aluminum pipes is that aluminum pipes of various specifications are diverted out of profiles through the splitting mold, and there will be a mold closing line.

| Features | Seamless aluminum tube | Seamed aluminum tube |

|---|---|---|

| Production Process | perforated extrusion | Split die extrusion method |

| Features | The inner and outer surfaces are smooth and seamless, with high compressive strength, high temperature resistance, good corrosion resistance, and can be bent. | The compressive strength and corrosion resistance are average, and it is easy to crack when bending, but the process is mature and the cost is low. |

| use | Pressure vessels, chemical equipment, shipbuilding and other industries, such as reactors, heat exchangers, oil and gas pipelines in oil and gas industries, etc. | Machinery, automobiles, aircraft, building materials, etc., such as coolers, heaters, etc. |

Direct extrusion VS indirect extrusion

Direct extrusion: During the direct extrusion process, the material flows out of the die hole in the forward direction of the extrusion axis, and the aluminum tube base material and the aluminum Extrusion Container move relative to each other.

Indirect extrusion: During the indirect extrusion process, the material flows out of the die hole in the opposite direction of the extrusion axis, and there is no relative movement between the aluminum tube base material and the aluminum extrusion container.

| Features | Direct extrusion | Indirect extrusion |

|---|---|---|

| surface | good | Not very good |

| cycle | long cycle | Short cycle |

| size | Limited size, maximum extrusion outer diameter is relatively small | Large maximum extrusion outer diameter |

| Energy consumption | High energy consumption | Low energy consumption |

| deformation | Deformation is relatively uneven | Uniform deformation |

| Yield | Lower | Higher |

Welding skills and precautions for aluminum alloy pipes

Aluminum pipe welding process

Gas welding and electrode arc welding methods, the equipment is simple and easy to operate.

Inert gas shielded welding (TIG or MIG) method is the most widely used welding method of aluminum and aluminum alloys.

Aluminum pipe welding precautions

- Material preparation: Prepare both ends of the aluminum tube and pipe to remove oxides and dirt on the surface

- Welding machine and equipment preparation: Select appropriate welding equipment and set parameters.

- Welding position selection: Make sure the welding position of the aluminum alloy pipe and tube is flat and without skew.

- Welding method selection: TIG and MIG can be used for aluminum tube and pipe welding.

- Protective gas flow control: maintain appropriate protective gas flow.

- Welding speed control: control the welding speed

- Post-welding treatment: cleaning, grinding and dust removal of the welding area

Transactions and Services

- Production standards: GB, EN, ASTM, AISI, JIS, DIN or other standards required by customers.

- Price Term: CIF CFR FOB EX-WORK

- Payment Term: TT, LC at sight, WestUnion,

- Package Type: Standard seaworthy export packing with craft paper, anti-blushing agent, transparent plastic protective film, wooden pallets. or according to the customers' request for aluminum tubing

- MOQ: Generally, the trial order will be accepted. The MOQ can be confirmed according to the different products. (100kgs for ready stock)

- Supply Ability: 2, 000 Tons per Month

Why choose us?

Xienuo Enterprise is a professional aluminum tube manufacturer in China. We have 6 aluminum tube extrusion production lines, which can produce seamed aluminum tubes, seamless aluminum tubes, and aluminum tube molds of various sizes. We can customize a wide range of special Shaped extruded aluminum profiles, you can contact us for custom production.

Product advantages:

- The surface is clean and free of oil stains.

- Smooth and burr-free.

- The equipment is advanced and complete, and can produce seamed aluminum tubes or seamless aluminum tubes according to demand.

- Complete testing equipment.

Additional services: sawing, bending, anodizing, electrophoresis, spraying, polishing, drawing, etc.

Product certification: CE, ISO9001, etc.

Product testing: Test items are based on customer needs and support third-party testing.